If you’re an owner or operator of a Freightliner, knowing how to spot a failing air conditioning condenser can save you a ton of hassle. This article is poised to guide you through recognizing the telltale signs that your Freightliner’s air conditioning condenser is on the brink of breakdown. So, you can stay ahead of costly repairs and enjoy a comfortable, cool ride even during the hottest months. Ensuring your vehicle is in peak condition doesn’t have to be a guessing game – let’s get you equipped with the knowledge you need to keep cool on the road.

Understanding the Role of the AC Condenser in a Freightliner

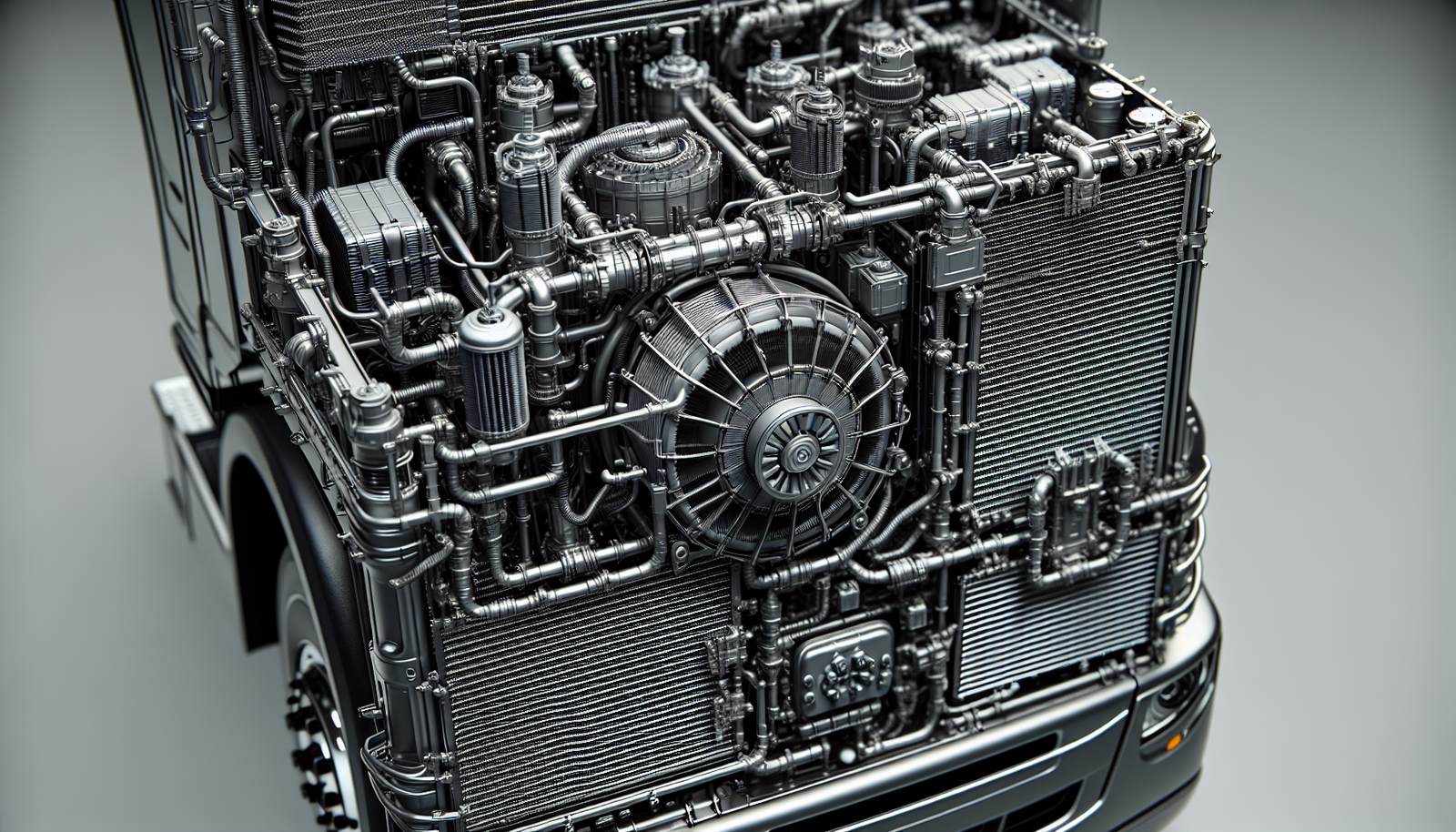

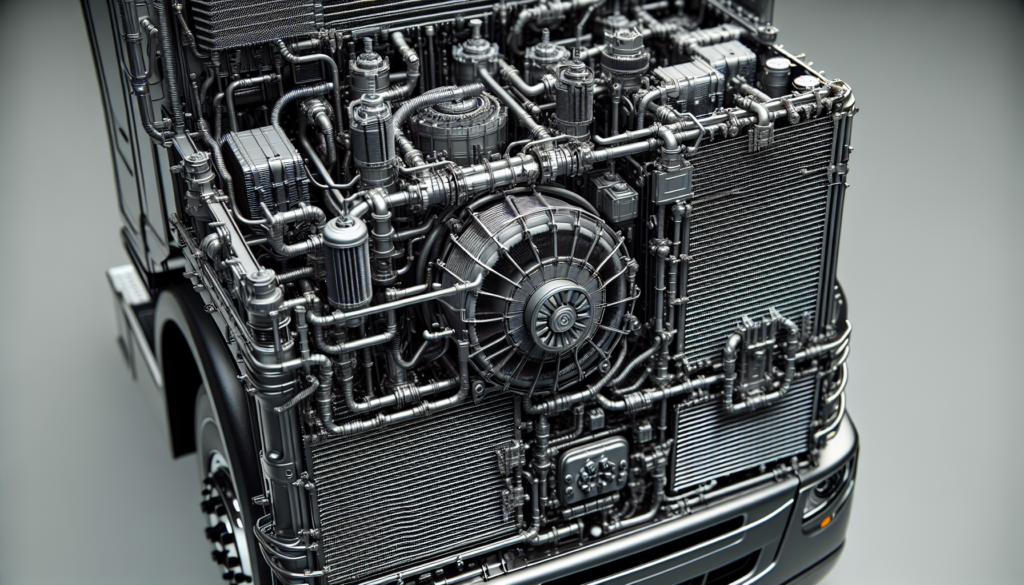

Your Freightliner truck is a massive machine with complex internal systems. One of these systems is the air conditioner (AC), a critical component for driver comfort. At the heart of the AC system is the condenser, which plays a central role in cooling the cabin. Understanding its function is key to maintaining your Freightliner’s performance.

Important Functions of the AC Condenser

The AC condenser serves as the main heat exchanger in your Freightliner’s air conditioning system. It is responsible for cooling the refrigerant that flows through it and transforming it from gas to liquid, a crucial part of the cooling process. As the AC condenser manages heat energy transfer, it directly impacts the overall cooling efficiency of your truck’s AC system.

How the AC Condenser Affects Comfort in Freightliner

Your comfort inside your Freightliner is largely dictated by the AC condenser. It is the component responsible for removing heat from the cabin, making you feel cooler. A properly functioning AC condenser also helps maintain consistent cabin temperature, ward off excess humidity, and prevent the truck’s windshield from fogging up. If the AC condenser fails, it could lead to a myriad of issues, including uncomfortable cabin temperatures.

Damage Risk Factors for Freightliner Condensers

Several factors can cause damage to your Freightliner’s AC condenser. These risk factors include severe weather conditions, physical damages like impact from road debris, system corrosion, and wear and tear due to normal usage. It’s important to be aware of these risk factors so you can take necessary preventive measures and promptly address any signs of damage.

Temperature Fluctuations Inside the Cabin

One clear sign of a failing AC condenser in your Freightliner is inconsistent cabin temperatures. This can be seen as either inconsistent cooling or overall overheating, despite the air conditioner being turned on.

Inconsistent Cooling: High and Low Temperatures

If you’ve noticed fluctuating temperatures inside your Freightliner, your AC condenser could be at fault. When functioning normally, the condenser converts refrigerant from a high-temperature gas to a cooled liquid. If it’s compromised, it won’t be able to transfer heat efficiently, leading to inconsistent cooling.

Overheating Inside the Freightliner

Conversely, overheating in your Freightliner is another telltale sign of a failing condenser. When the condenser fails to cool the refrigerant properly, it cannot effectively remove heat from your truck’s cabin, leading to an uncomfortably warm environment.

Cold Air Not Produced Even When AC is On

If the air coming from your air vents doesn’t get cool despite the AC running, it’s a red flag that the AC condenser may have issues. The absence of cool air is generally a sign that the condenser is no longer capable of completing its heat exchange function effectively.

Unusual Noises Coming from the AC

Your Freightliner’s AC system should operate quietly and smoothly. Any new or unusual noises from the AC system could indicate possible problems with various components, including the AC condenser.

Rattling or Buzzing Sounds

Rattling or buzzing sounds are commonly associated with a failing AC condenser. These sounds can originate from loose components within or around the condenser unit, refrigerant pressure problems, or a failing condenser fan motor.

Identifying Sound Sources in the Freightliner: AC Condenser

Locating the exact source of the noise in your Freightliner can be challenging. However, it’s essential to recognize the potential role of your AC condenser in producing these noises. If your AC system is still producing noises even after other parts have been inspected, your AC condenser may be the culprit.

Possible Causes of Unusual Noises in the AC Condenser

Unusual noises can originate from various issues, including refrigerant leakage, a compromised fan motor, or damaged condenser coils rattling against each other. A professional inspection should identify the root cause and repair it as needed.

Detecting Strange Odors Inside the Truck

You should pay attention to any unusual odors inside the Freightliner. They can be a yellow flag that something’s wrong with your AC condenser or other AC components.

Smell of Burning or Hot Wiring

If you perceive burning smells, it could indicate overheating issues with the AC condenser unit or its electrical connections, potentially indicating a failing AC condenser.

Moldy or Musty Smells: Indication of AC Condenser Leak

Moldy or musty smells often point to a moisture problem. If there’s a leak in the AC condenser, excess moisture can accumulate and breed mold and mildew, producing this distinct odor.

Ozone-like Smell: A Sign of Electrical System Overload

An ozone-like smell can mean that electrical components in your AC system, like the condenser unit, could be overloaded. This could lead to a part failure and requires immediate attention.

Frequent Overheating of The Engine

Overheating in your Freightliner’s engine could be linked to a compromised AC condenser. It could indirectly affect the efficiency of the truck’s cooling system, leading to engine overheating.

Link Between Engine Overheating and AC Condenser Failure

When your AC condenser fails, it essentially stops dissipating heat from your truck’s cabin. This increases the load on your engine’s cooling system, which may already be working hard, especially in hot weather. This increased burden can lead to engine overheating.

Increased Cooling System Pressure

A failing AC condenser can also cause increased pressure within the cooling system. When the condenser can’t cool the refrigerant sufficiently, the system has to work harder, building up pressure. This increased pressure can also contribute to the overheating issue.

Damaged Cooling Fans Effect on Engine Overheating

The AC condenser’s cooling fans play a vital role in managing heat within the AC system. If they’re damaged or failing, they won’t be able to help cool the air as efficiently, making the engine prone to overheating.

Leaking Fluid or Refrigerant Fluid

Leaking fluid around the AC condenser could be a clear sign of a failing condenser. It’s vital to frequently check the refrigerant level in your Freightliner and take note of any drastic drops.

Signs of Leaks Around the AC Condenser Area

If you see visible liquid around the AC condenser area, it might suggest that the condenser is leaking refrigerant. This can be a result of physical damage, ageing, or system pressure causing cracks or breaks in the condenser parts.

Importance of Regular Refrigerant Level Check in Freightliner

Regularly checking your Freightliner’s refrigerant levels is crucial as it allows you to notice any sudden drops or slow leaks in your AC system, potentially preventing larger problems down the line.

Adverse Effects of Low Refrigerant in Freightliner AC System

Low refrigerant levels pose a severe challenge to your AC system’s effectiveness. This can result in less efficient cooling, increased pressure within the system, and possible damage to other components when your AC system has to overwork.

Restricted Airflow from the AC Vents

Less airflow from your AC vents is a common sign of a failing AC condenser in your Freightliner. The blockage in the AC condenser can affect the efficiency of the overall AC system.

Possible Blockage in the AC Condenser

Obstructions in the AC condenser, often caused by debris like leaves, dust, or bugs, can prevent air from flowing freely through the condenser coils. This could decrease the effectiveness of the condenser and reduce the overall airflow from your AC vents.

How Accumulated Debris Affects AC Condenser Efficiency

Accumulated debris can block the condenser coils and restrict heat transfer, reducing the AC condenser’s efficiency. This can result in less cool air circulating throughout the Freightliner’s cabin, leading to an uncomfortable driving environment.

Signs of Airflow Reduction in Freightliner Cabin

Airflow reduction can be quite noticeable. If you feel less air coming from your vents, or if the air doesn’t get cool despite your AC being on, the reduced airflow might be due to problems with your AC condenser.

Poor Fuel Efficiency in your Freightliner

Believe it or not, a failing AC condenser could indirectly lead to poor fuel efficiency in your Freightliner. The extra strain put on the system by a failing condenser can increase fuel consumption.

Connection Between AC Function and Fuel Consumption

Your AC system, especially the AC condenser, plays a role in your overall fuel consumption. Since the AC system uses power from the engine—which uses fuel—any issue forcing the AC system to overwork can end up consuming more fuel.

How a Faulty AC Condenser Affects Freightliner’s Fuel Efficiency

A faulty AC condenser can put undue stress on your Freightliner’s engine, requiring more power and hence, increasing fuel usage. If you notice a sudden decrease in your truck’s fuel efficiency, it’s essential to check your AC system, including the AC condenser.

Improving Efficiency with Regular AC Condenser Inspections

Regular AC condenser inspections can help improve fuel efficiency. They’ll catch any potential problems with the condenser early on, before they become more severe and affect the truck’s overall performance, including fuel efficiency.

Visible Damage to the AC Condenser Unit

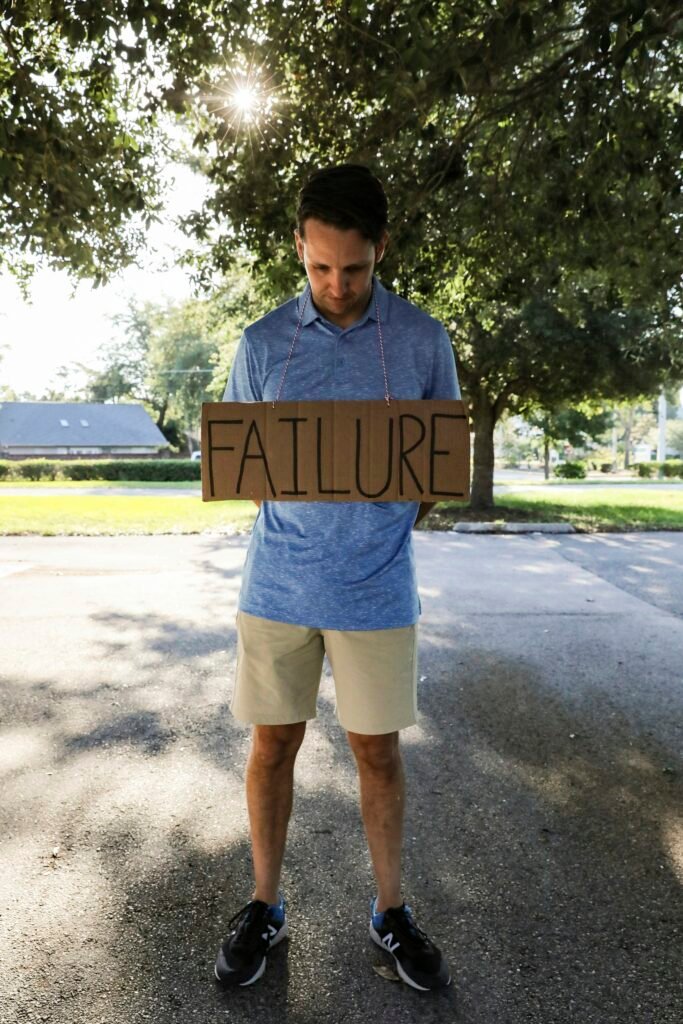

Visible damage to the AC condenser unit is a clear sign that it’s time for a repair or replacement. Regularly inspecting your Freightliner’s AC condenser can help prevent minor damages from becoming major ones.

Checking for External Damages to AC Condenser in Freightliner

Regularly inspect your Freightliner’s AC condenser for any visible signs of damage, such as corrosion, cracks, or holes. Make sure also to check the condenser fan for any signs of damage or wear, as this can directly affect the condenser’s performance.

Link Between Physical Damage and AC Performance

Physical damages to the AC condenser can hinder its ability to cool the refrigerant effectively, leading to poor AC performance. Additionally, physical damages can also cause refrigerant leaks, further reducing your AC system’s efficiency.

When to Consider AC Condenser Replacement

Regular inspections and maintenance can extend your AC condenser’s lifespan. However, at some point, you may need to consider replacing it—especially if it’s damaged or aged or if it has been causing issues in your AC system despite repeated repairs.

Regular Need for AC Recharge

Regularly needing to recharge your AC system could be a sign of a problem. While an occasional recharge is normal, frequent recharges could indicate a failing AC condenser.

How Often Should Freightliner AC be Recharged?

As a rule of thumb, your Freightliner’s AC system should be recharged every two years. However, this can vary based on factors including vehicle usage and the health of the AC system.

Regular AC Recharge as an Indication of AC Condenser Failure

If you find yourself needing to recharge your AC system more frequently than every two years, it could point to a failing AC system, possibly a faulty or failing AC condenser. Regular recharges could indicate that your AC system is not cooling the air as it should, overworking, or leaking refrigerant.

Effects of Repeated AC Recharge on Freightliner’s Long-Term Performance

In the long term, regular AC recharges could have adverse effects on your Freightliner’s performance. It could force the truck’s engine to work harder, consume more fuel, and can potentially damage other AC system components. That’s why it’s crucial to diagnose and address any issues causing the need for regular recharges promptly.

In conclusion, being aware of the role of the AC condenser in your Freightliner and recognizing early signs of failure can prevent uncomfortable temperatures, noises, smells, and even mechanical failures in your truck. Regular maintenance and inspection of your AC condenser are vital in maintaining a comfortable cabin environment and your Freightliner’s overall performance.