As the seasons shift and you find yourself using the air conditioning in your Freightliner Cascadia less frequently, it’s crucial to give the system the attention it needs to ensure longevity and peak performance when the heat returns. Maintaining your truck’s AC during these off-season periods can save you from unexpected repairs and ensure a cool, comfortable ride when the temperatures soar again. This article will guide you through the essential steps to take care of your air conditioning system, keeping it in tip-top shape even when it’s not in daily use, so you’re never caught off guard by a sputtering AC on a hot summer day.

Understanding the Freightliner Cascadia AC System

Components of the AC system

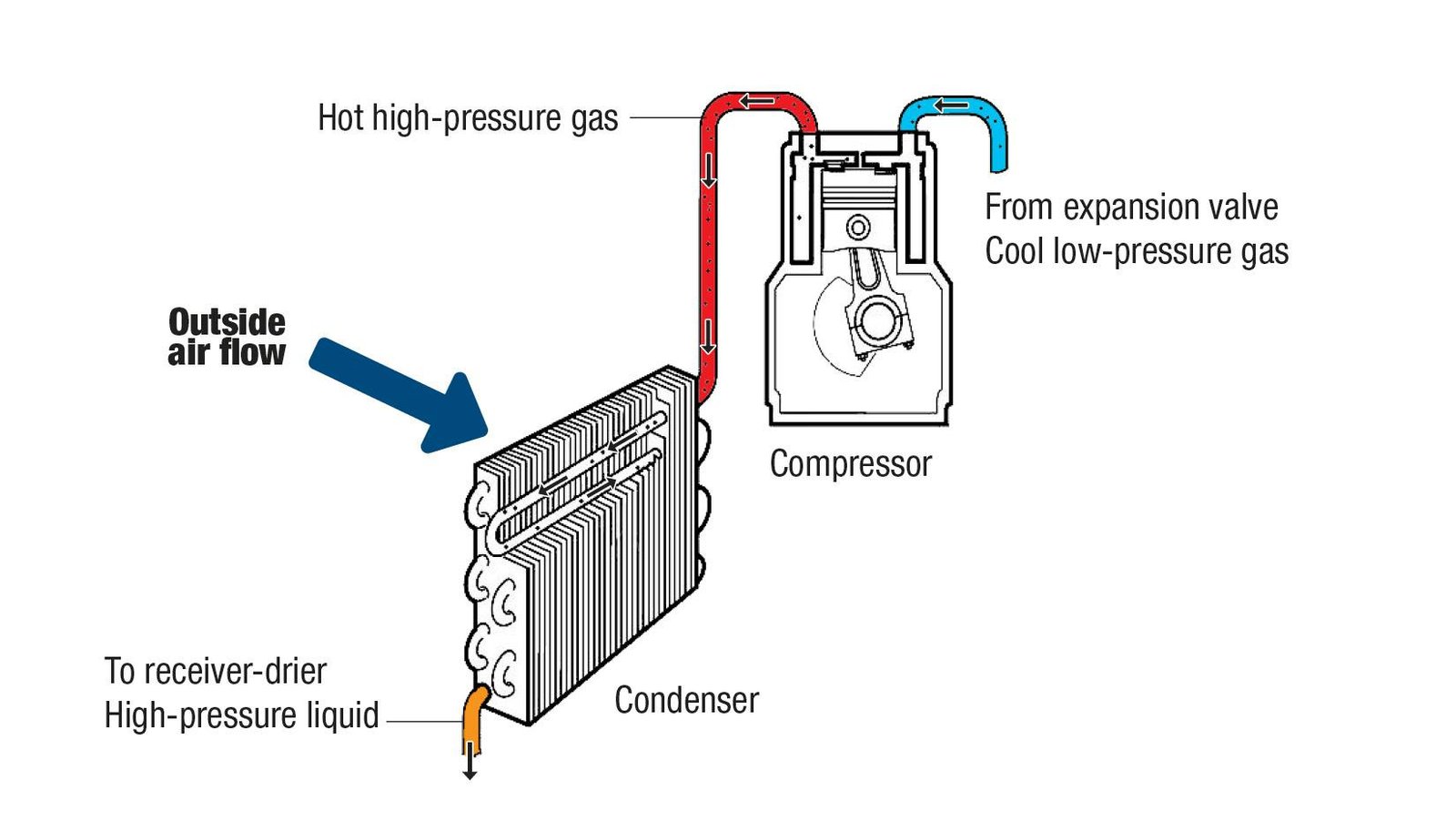

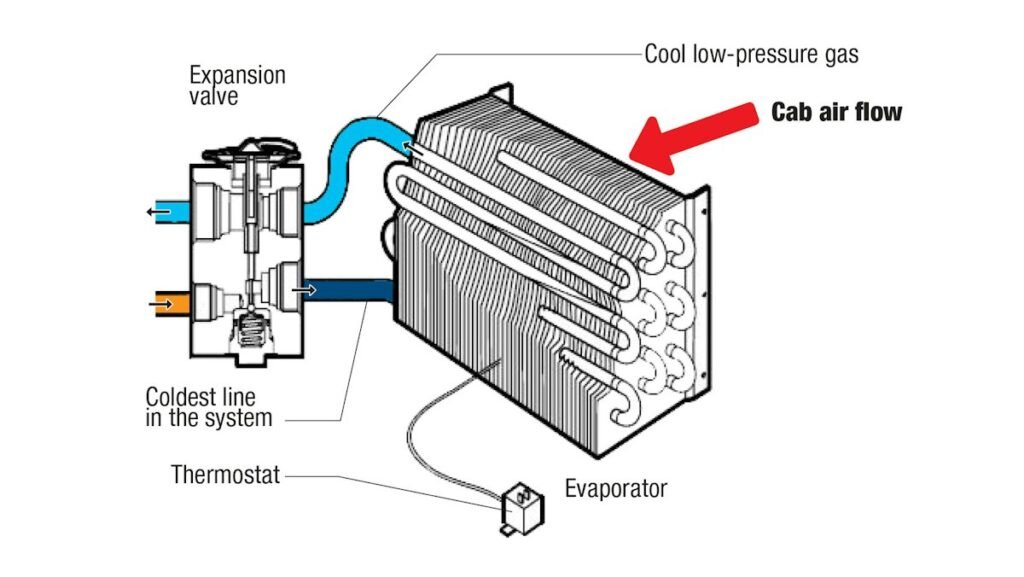

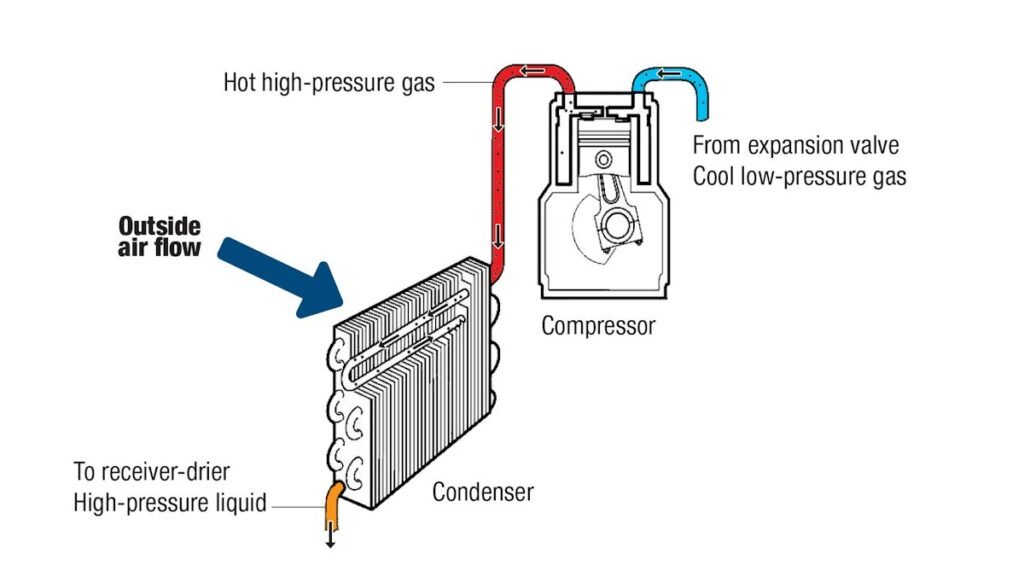

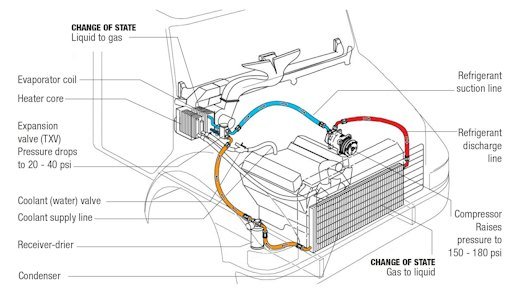

Your Freightliner Cascadia’s AC system is a marvel of modern engineering, designed to keep you comfortable throughout your long hauls. It consists of several key components: the compressor, condenser, evaporator, expansion valve, and receiver drier. Each part plays an essential role in the cooling process. The compressor pumps refrigerant through the system; the condenser dissipates heat as the gas refrigerant converts to liquid; the evaporator absorbs heat from the cabin air; the expansion valve regulates refrigerant flow, and the receiver drier removes moisture and contaminants.

Functioning of the Cascadia AC during regular use

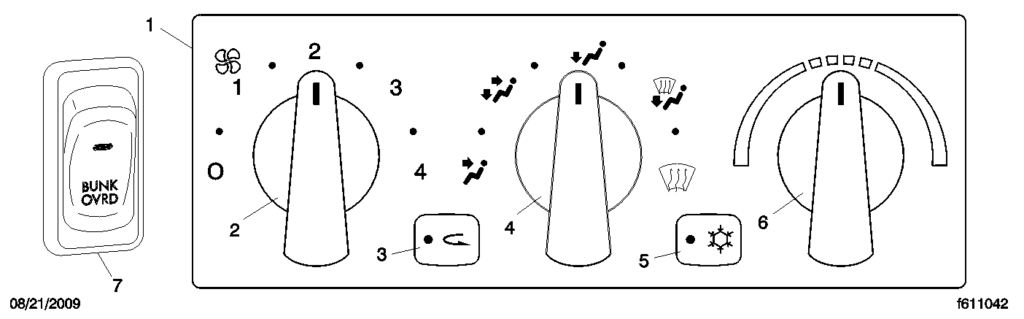

During regular use, your Cascadia’s AC system works tirelessly to maintain a pleasant cabin temperature. When you adjust the controls to your desired level of comfort, the system responds accordingly, ensuring that the refrigerant flows through the closed loop, absorbing heat from inside the truck and releasing it outside, effectively cooling down your space.

Importance of off-season maintenance

But what about during the off-season when you’re not using the AC as often? Maintaining your AC system during this time is critical to ensure it performs optimally when you need it again. Off-season maintenance prevents the buildup of harmful substances, and addresses the potential for system degradation, ensuring that when the warmer months roll around, your AC is ready to keep you cool without a hitch.

Seasonal Inspection Routines

Scheduling professional inspections

At the turn of each season, it’s prudent to schedule a professional inspection of your Cascadia’s AC system. A trained technician will have the expertise to comprehensively assess and tune-up the system, ensuring it’s in prime condition for when the temperature starts to climb.

Critical checkpoints for AC inspections

During these inspections, several critical checkpoints are given special attention: the state of the compressor, the integrity of the condenser and evaporator coils, the functionality of the expansion valve, and the condition of the belts and hoses. A professional will also check for signs of refrigerant leakage and any potential electrical issues.

Assessing wear and tear after peak usage seasons

Particularly after peak usage seasons, it’s important to assess the system for wear and tear. Components like the compressor and the belts may show signs of stress or damage. Addressing these issues promptly can spare you from a more costly and inconvenient breakdown later.

Cleaning the System Components

Cleaning the condenser and evaporator coils

Keeping the condenser and evaporator coils clean is paramount for efficient system operation. You should regularly remove any dust, dirt, or grime buildup, which can inhibit heat transfer and cause the system to work harder, decreasing its efficiency.

Replacing or cleaning air filters

Air filters trap pollen, dust, and other airborne particles, and over time can become clogged. For consistently clean air and efficient operation, replace or clean these filters as recommended by the manufacturer.

Removing debris and checking for blockages

Lastly, check for blockages and remove any debris that might have accumulated around your Cascadia’s AC components. Debris can obstruct airflow and refrigerant lines, again impeding the system’s efficiency.

Refrigerant Management

Checking refrigerant levels

Spotting and correcting refrigerant levels is key. Low refrigerant not only reduces cooling power but can also mean there’s a leak, which a technician will need to repair.

Detecting leaks and repairing as needed

Leaks in the AC system can come from corrosion, loose connections, or damaged components. A leak not only depletes refrigerant but can also introduce moisture, leading to further complications.

Refrigerant recharge and handling regulations

Should your system need a refrigerant recharge, be mindful that specific handling regulations are in place for environmental protection. It’s also a job for professionals who have the tools and certification to handle refrigerants safely.

Climate Control Considerations

Adjusting for humidity and temperature changes

Your Cascadia’s cab is not just a driving space; it’s your home on the road. Adjusting your AC system for changing humidity and temperature levels is essential for your comfort and the preservation of interior materials.

Importance of consistent internal climate during storage

If you’re storing your truck, maintain a consistent internal climate to protect the cabin and the AC components from extreme temperature fluctuations and moisture, which could lead to mold or mildew.

Using dehumidifiers and ventilation

Consider using dehumidifiers and ensuring proper ventilation even during storage. This not only maintains an ideal environment but also helps keep the AC system fresh.

Electrical System Checks

Checking the AC system’s electrical connections

Periodically, check your AC system’s electrical connections, as these can become loose or corroded over time. Tight, clean connections are vital for an efficient and safely operating AC system.

Battery maintenance during off-seasons

Odd as it may sound, battery maintenance can impact your AC system. A well-maintained battery ensures that the AC’s electronic components receive consistent power, preventing malfunctions and premature wear.

Dealing with corroded wires and connectors

If you discover corroded wires or connectors, address them quickly. Corrosion can lead to poor conductivity and system failures. Clean connections will ensure your AC system’s reliability.

Lubrication and Moving Parts

Lubricating the compressor and other moving parts

Lubrication is to your AC system’s moving parts what water is to your body – essential. Keep the compressor and other moving parts well-lubricated to prevent friction, heat, and wear.

Keeping the belts and pulleys in good condition

Belts and pulleys should remain tight and in good shape for your AC system to operate efficiently. Check for any signs of wear or damage and replace them as necessary to avoid a breakdown.

Preventative measures for mechanical failures

Taking preventative measures can save you from mechanical failures down the road. Regular checks, timely replacement of worn parts, and proper tensioning of belts can make a world of difference.

Protective Measures for Prolonged Downtime

Using protective covers

When faced with prolonged downtimes, consider using protective covers over the exposed parts of your AC system. This simple act can prevent dust accumulation and safeguard the components from the elements.

Benefits of periodic system operation

Periodically operating the system, even when it’s chilly out, can keep the AC’s parts moving and lubricated. This prevents seals from drying out and refrigerant from settling – both common issues after extended periods of inactivity.

Avoiding condensation and corrosion risks

To avoid risks associated with condensation and corrosion, keep your Cascadia’s storage space dry and well-ventilated. Doing so can significantly prolong the life of your AC system.

Monitoring and Diagnostics

Utilizing built-in diagnostic systems

Many modern Freightliner Cascadias come equipped with diagnostic systems that monitor the health of the AC. Utilize these tools to keep an eye on performance and catch issues before they escalate.

Recording performance data

Keep records of your system’s performance data throughout its operation. This information can be invaluable for forecasting potential issues or determining service intervals.

Early detection of potential issues

The early detection of operational inconsistencies can be the key to avoiding larger, more complex problems. Keep vigilant and act quickly at the first sign of trouble.

Documentation and Maintenance Records

Keeping a log of maintenance activities

Documenting all your maintenance activities provides a clear history of your AC system’s care. It helps you keep track of what has been done, and what needs to be done, serving as a guideline for consistent upkeep.

Warranty considerations and compliance

Ensure your maintenance activities comply with warranty terms. Following the manufacturer’s guidelines for service not only keeps your system in top condition but can also protect you from voiding your warranty.

Planning for future maintenance based on historical data

Your past maintenance records are a treasure trove of information when planning for the future. Analyzing historical data will aid in predicting when parts might fail and when to schedule service, helping you avoid unexpected downtime and expense.

Remember, maintaining the air conditioning system in your Freightliner Cascadia during off-season periods is just as important as caring for it during the summer months. By sticking to these recommendations, you’ll enjoy a comfortable cabin environment year-round and extend the life of your AC system.