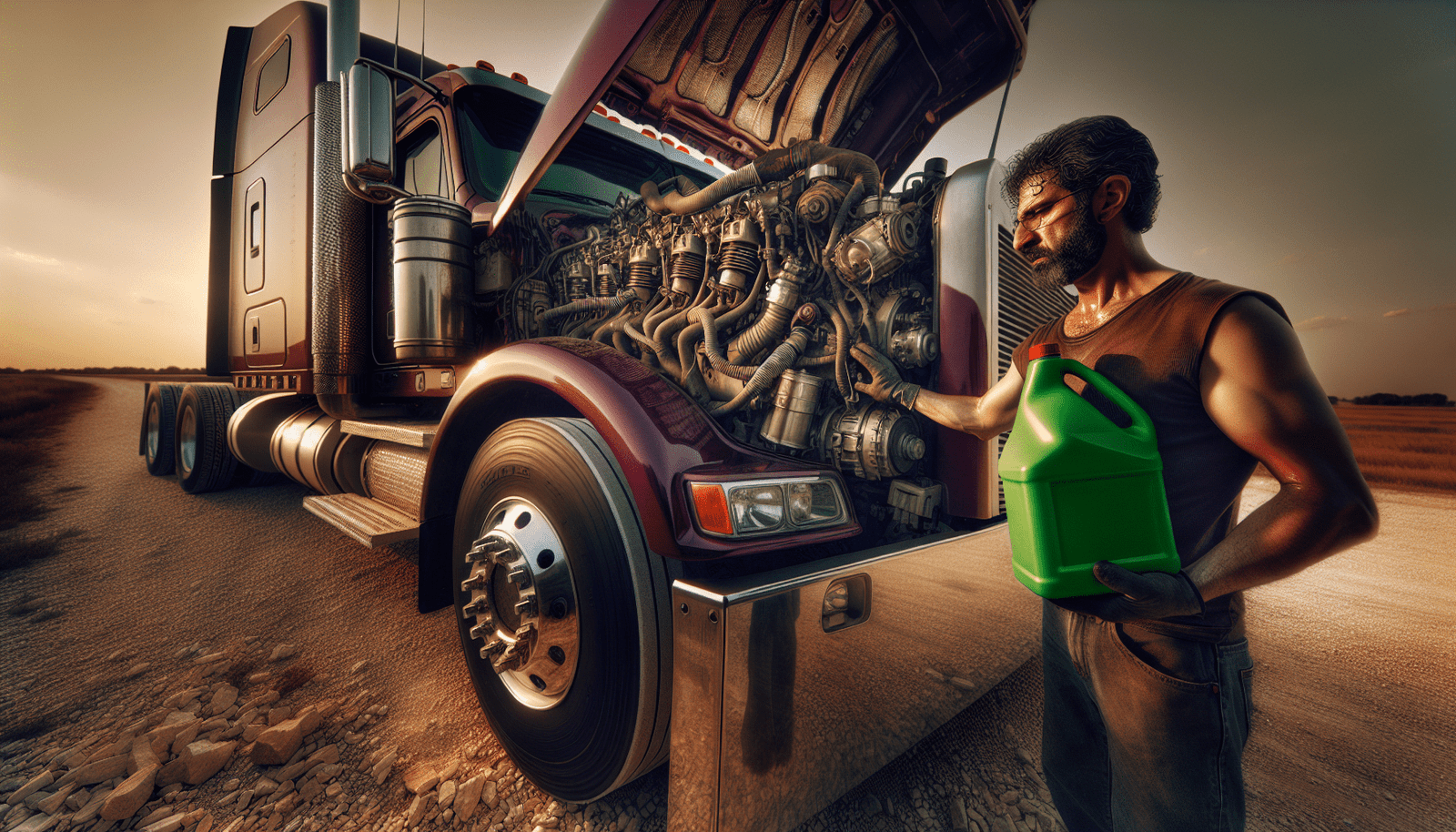

Navigating the maintenance of your Freightliner engine can often present a mix of quick decisions and precise actions, especially when it comes to managing your engine’s coolant levels. One commonly faced dilemma is whether you should add coolant to a hot engine right off the bat or patiently wait for it to cool down first. This crucial choice can significantly impact the well-being of your vehicle. Understanding the best approach requires a blend of mechanical insight and safety considerations, ensuring your engine runs smoothly without causing any unintended harm.

Understanding Coolant System

Role of Coolant in Engine Performance

The coolant plays a pivotal role in your vehicle’s performance. It’s tasked with the crucial job of absorbing and dissipating the immense heat generated by your engine during operation. This not only prevents your engine from overheating but also ensures it operates within an optimal temperature range. By maintaining the right temperature, the coolant helps in enhancing engine efficiency, reducing emissions, and prolonging the lifespan of engine components.

How the Coolant System Works

Understanding how the coolant system works will help you appreciate its significance. The process begins with the coolant absorbing engine heat, then circulating through the radiator where it’s cooled by air. This cycle is continuous while your engine is running, ensuring the engine’s temperature remains within safe limits. The coolant system includes several components, such as the water pump, radiator, thermostat, and various hoses which work together seamlessly to achieve this cooling effect.

Differences Between Various Coolant Types

Not all coolants are the same. They come in different types, primarily distinguished by their chemical composition and the protection they offer. Ethylene Glycol and Propylene Glycol are two common types, with specific variations designed for different engine types and climates. These coolants might also have additives to prevent corrosion, enhance heat transfer, or reduce foaming. Choosing the right coolant depends on your vehicle’s specifications and the manufacturer’s recommendations.

Risks of Adding Coolant to a Hot Engine

Thermal Shock and Engine Damage

Adding coolant to a hot engine can lead to thermal shock, a condition where rapid temperature changes cause engine materials to contract suddenly. This can result in cracks or damages to the engine block or other components, leading to costly repairs.

Risk of Personal Injury from Steam or Hot Coolant

When you open the coolant reservoir or radiator cap of a hot engine, the sudden release of pressure can cause hot steam or coolant to spray out, posing a severe risk of burns.

Potential for Warping Engine Components

The intense heat in a hot engine could cause metal components to expand. Adding coolants suddenly might cool some parts too quickly, leading to uneven contraction and potentially warping critical components.

Benefits of Waiting for the Engine to Cool

Preventing Damage to the Engine

By waiting for the engine to cool before adding coolant, you minimize the risk of thermal shock and the ensuing damage. This patience can save you from expensive engine repairs down the line.

Safety Considerations

Letting the engine cool substantially reduces the risk of personal injury caused by steam or splashing coolant. This safety measure is crucial to prevent burns or other injuries.

Ensuring Accurate Coolant Level Measurements

Hot engines can give misleading coolant level readings due to expansion. Waiting allows for more accurate measurements, ensuring you add the correct amount of coolant without overfilling.

How to Safely Check Coolant Levels

Properly Opening the Radiator Cap

Before opening the radiator cap, ensure the engine is cool. Wrap a cloth around the cap to protect your hand, then slowly twist it to release any pressure before fully opening.

Using Protective Gear

Wearing protective gear, including gloves and safety glasses, can guard against accidental splashes of coolant, which can be harmful to your skin and eyes.

Identifying the Coolant Reservoir

The coolant reservoir is typically a transparent container located near the radiator. Check for “coolant fill line” markings to ensure you’re looking at the right reservoir and adding the correct amount.

Symptoms of Low Coolant Levels

Engine Overheating

One of the first signs of low coolant levels is engine overheating. If your temperature gauge is consistently high, it’s time to check your coolant levels.

Visible Leaks Under the Vehicle

Puddles of coolant under your vehicle indicate a leak in the cooling system, leading to low coolant levels and potential overheating.

Warning Lights on the Dashboard

Modern vehicles have warning lights that alert you when coolant levels are low or if there’s an overheating issue, prompting you to check the coolant system.

Steps to Cool Down Your Freightliner Engine

Turning Off the Engine

If you suspect your engine is overheating, the first step is to turn off the engine. This halts further heat generation.

Allowing Engine to Cool Naturally

Let the engine cool down naturally. Opening the hood can accelerate this process, but never attempt to open the radiator cap while the engine is hot.

Checking for External Indications of Overheating

Inspect for any signs of leaks or damage that could indicate overheating or a malfunction in the cooling system.

How to Properly Add Coolant to Your Engine

Selecting the Right Type of Coolant

Ensure you choose a coolant that matches your vehicle manufacturer’s recommendations to maintain engine integrity and performance.

Mixing Coolant and Water Appropriately

If your coolant isn’t pre-mixed, follow the manufacturer’s guidelines for mixing coolant and water—typically a 50/50 ratio—to achieve the proper antifreeze and coolant balance.

Gradually Filling the Coolant Reservoir

Slowly add the coolant to the reservoir, avoiding overfilling. Fill it to the designated “full” line and replace the cap securely.

Common Mistakes When Adding Coolant

Adding Coolant to the Wrong Reservoir

Ensure you’re adding coolant to the coolant reservoir and not another fluid reservoir by mistake, which could damage your vehicle.

Filling Beyond the Maximum Line

Overfilling can cause excessive pressure in the system, leading to leaks or damage. Always adhere to the recommended fill levels.

Neglecting to Check for Leaks After Addition

After adding coolant and running your engine, check for any new leaks, which could indicate a problem that needs addressing.

When to Seek Professional Help

Persistent Overheating Issues

If your engine continues to overheat despite adding coolant, there could be a deeper issue requiring professional diagnosis and repair.

Signs of Coolant System Damage

Visible damage, such as cracks or leaks in the cooling system components, warrants an expert’s attention.

Uncertainty About Coolant Types and Ratios

If you’re unsure about the correct coolant type or mix ratio for your vehicle, it’s prudent to consult with a professional to avoid mistakes.

FAQs About Adding Coolant to Freightliner Engines

Can I drive immediately after adding coolant?

Yes, but it’s advised to let the engine run for a few minutes to circulate the coolant and check for leaks or warning signs of overheating.

How often should coolant levels be checked?

It’s a good practice to check your coolant levels at least once every month and before embarking on long trips.

What are the signs of a faulty coolant system?

Signs include overheating, leaks, fluctuating temperature readings, and coolant warning lights on the dashboard. Identifying these early can prevent major repairs.

In conclusion, adding coolant to your Freightliner engine requires care and understanding of how the cooling system works. Always prioritize safety by allowing your engine to cool down before adding coolant. This not only ensures your safety but also protects your engine from potential damage. Regular checks and maintenance of your cooling system can go a long way in preserving the performance and longevity of your vehicle.