Ever wondered why the heater in your Freightliner isn’t working as it should? It could be because of low coolant levels. This article intricately explains how coolant levels in your Freightliner might be impacting the heater’s performance and what corrective measures you can take. You’ll gain an understanding of the potential causes and solutions that might just save your day during those chilly winter months. Your Freightliner deserves the best care, and you’re just one step away from learning how. Let’s embark on this journey to demystify the relationship between the coolant in your Freightliner and your heater’s functionality.

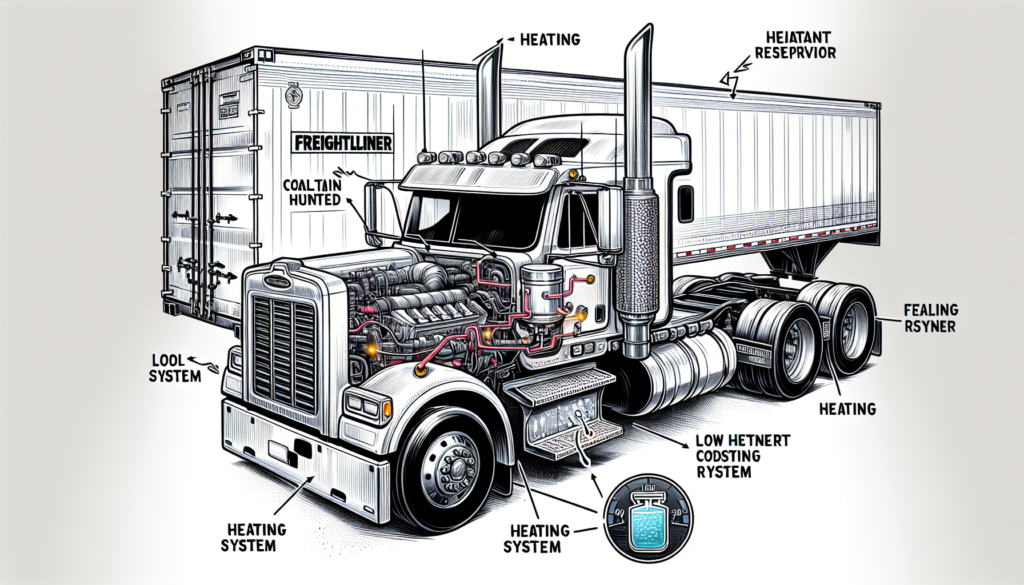

Understanding Your Freightliner’s Heating System

In your journey as a Freightliner owner, it’s essential to comprehend how the heating system functions. Whether driving during chilly mornings or frosty nights, a well-functioning heating system could be the difference between sluggish unfriendly cruises and smooth comfortable voyages.

Basics of Freightliner Heating Mechanics

Your Freightliner’s heating systems operate in a straightforward process. The heating system relies on the heat generated by the engine to warm the cab. As your engine runs, it creates heat, which warms the coolant running through the engine block. The warmed coolant then proceeds to the heater core, a small radiator inside your dashboard, where a fan distributes the heat into the cab.

Role of Coolant in the Heating Process

The coolant, also known as anti-freeze, plays an integral role in your Freightliner’s heating system. The primary role of the coolant is to absorb and transfer the heat produced by your engine to the radiator and then to the heater core, effectively heating your vehicle. Simply put, without enough coolant, your heater may not function correctly.

Common Heating System Components

Key components of your Freightliner’s heating system include the coolant, heater core, thermostat, and coolant reservoir. The role of each of these components is as important as the other. Without them, your heating system would be as good as non-existent.

Symptoms of Low Coolant in Freightliners

Just like any other mechanical vehicle, your Freightliner could develop problems related to low coolant levels. Here are common symptoms you should watch out for.

Visible Coolant Leaks

If you’re seeing bright-green, orange, or pink liquids on the ground underneath your Freightliner, that’s coolant. A leak is a clear sign that your coolant is running low, and it needs to be addressed sooner rather than later.

Decreased Heating Efficiency

The cabin not warming up as it used to? This might be due to low coolant levels. If coolant levels become too low, there may not be enough of it to circulate through the heater core, which will make it difficult to warm your Freightliner.

Dashboard Warning Lights

In more sophisticated Freightliner models, a warning light on the dashboard could indicate low coolant levels. However, you should not completely rely on this as not every coolant related problem can trigger the warning light.

The Link Between Coolant Level and Heater Function

So why is coolant so important to your heater’s functionality? The explanation relies on understanding the very mechanics of your vehicle’s heating system.

- How Coolant Circulation Affects Heater Output: Heater output is primarily affected by the amount of hot coolant that can be circulated through the heater core. A low coolant level may mean not enough of it reaches the heater core to produce sufficient heat, thus affecting its output.

- Consequences of Low Coolant on Heat Generation: Lower than needed coolant levels might not only affect heat output but also lead to engine overheating. This might result in costly damage to the engine and other associated components.

Diagnosing Heater Problems Related to Coolant

Diagnosis of heater problems related to coolant starts with checking the coolant level. If the level is right, the cause might be something else such as a bad thermostat, poor radiator cap seal, or a bad water pump.

Troubleshooting the Heating System

If you’re suspecting a problem, here are a few steps to troubleshoot your Freightliner’s heating system.

Checking for Proper Coolant Level

A quick check of your coolant reservoir will tell you if you have sufficient coolant. Always remember to check the coolant level when the engine is cold to avoid accidents.

Inspecting for Coolant Leaks

Coolant leaks, either internally or externally, can contribute to low coolant levels. Routine inspections can help detect and address these leaks before they cause significant harm.

Evaluating the Thermostat and Heater Core

A malfunctioning thermostat or blocked heater core could cause inadequate heat output. Having them examined can help prevent potential heating system problems.

Step-by-Step Guide to Checking Coolant Levels

Every Freightliner owner should know how to check coolant levels. Here’s a simple guide to help you out.

Safety Precautions Before Checking

Always ensure that the vehicle and engine are turned off and sufficiently cooled before checking coolant levels to avoid getting burned.

Locating the Coolant Reservoir

The coolant reservoir is often a translucent container located in the engine bay. Its location might vary depending on your Freightliner model.

Reading Coolant Level Indicators

On the side of the reservoir, there will be ‘minimum’ and ‘maximum’ marks. Coolant levels should always be between these two license marks when the engine is cold.

Refilling the Coolant System

If you find that your Freightliner’s coolant level is low, here’s how to go through the refilling process.

Selecting the Right Coolant Type

Not all coolants are created equal. Freightliners exclusively use a specific type of coolant so always refer to your owner’s manual to know the right one.

Procedures for Adding Coolant

With the right coolant at hand, slowly pour it into the reservoir until it reaches the ‘max’ mark. Always remember, your vehicle should be off and cool to prevent accidents.

Bleeding Air from the Cooling System

After adding the coolant, it’s essential to remove any air trapped in the system. You can do this by running your Freightliner, with the heater on full blast until it reaches its standard operating temperature.

Common Reasons for Low Coolant

Low coolant can arise due to several reasons. Here are a few common ones you might encounter.

External Coolant Leaks

Usually, the most common reason for low coolant levels is leaks originating from the radiator, water pump, heater core, or coolant lines.

Internal Coolant Leaks

Internal leaks often occur through the head gasket into the combustion chambers, making them harder to identify compared to external leaks.

Coolant Evaporation and Routine Loss

Coolants can also decrease overtime through natural evaporation or routine loss as your Freightliner operates, making routine coolant level checks and refills vital.

Preventative Maintenance for the Heating System

A comprehensive preventative maintenance routine can save you from potentially costly repair costs in the future.

Regular Coolant System Checks

Regularly checking your coolant system for leaks or coolant level drops helps keep your Freightliner’s heating system in check.

Flushing the Cooling System

Coolant flushing can remove any residues building up in the system. This operation is recommended every few years or specific mileage, as suggested by your vehicle’s manufacturer.

Replacing Aging Hoses and Clamps

Hoses and clamps that show signs of aging, such as cracks or rust, should be replaced to prevent potential leaks.

When to Seek Professional Help

If certain situations arise, it is recommended to bring it to a professional.

Persistent Heating Inefficiency

When heater inefficiency persists despite your maintenance efforts, seek a professional mechanic’s help to avoid potentially damaging critical engine components.

Reoccurring Coolant Loss

If your coolant levels keep dropping even after topping up, there might be a more serious issue underlying. A professional can diagnose this for you.

Complex Heating System Issues

Working with the heating system can be complex and dangerous. If you find yourself out of depth, it’s always safer to resort to a professional to handle it.

Leveraging Telematics Data for Preventative Heating System Care

Modern Freightliners offer a wealth of real-time data that can be used to optimize preventative care.

Using On-board Diagnostics for Heater Health

Utilizing your Freightliner’s on-board diagnostics can help detect issues before they become serious problems. Regularly check this information to ensure optimal heating system health.

Interpreting Data for Maintenance Planning

Interpreting the on-board diagnostic data correctly is crucial in planning and executing efficient maintenance practices for your Freightliner’s heating system.

Benefits of Real-time Coolant Monitoring

Real-time coolant monitoring aids in detecting low coolant levels, overheating, or coolant leaks promptly, enabling early intervention and preventing costlier repairs down the line.

To conclude, understanding the integral role of coolant in your Freightliner’s heating system is essential in ensuring its long-term performance and your comfort on the road. Regular maintenance and immediate attention to any coolant-related problems will ensure a healthy heating system and prolong your Freightliner’s lifespan.