In the exciting world of long-haul trucking, your Freightliner is your second home and your heater – a boon during those chilly winter months on the road. Imagine a scenario where your trusted companion suddenly loses its warmth, turning your comfortable environment into an icebox on wheels. The culprit behind this discomfort could be a problematic blower motor. As you navigate this article, you’ll learn about the critical role of the blower motor in your Freightliner’s heating system, how its malfunction can affect the effectiveness of your heater, and what you can do to fix it. Let’s get you back on the road in warmth and comfort.

Understanding the Function of a Blower Motor

The blower motor is a critical component of your heating and cooling system, acting as the central force that drives air through your vehicle’s HVAC system. Understanding its function can help you identify any potential issues early and maintain your Freightliner’s heating capabilities effectively.

Role of the blower motor in heating systems

In essence, the blower motor’s main function in a heating system is to propel warm air through the ducts and vents. It takes warm air provided by the heater core and circulates it throughout your cabin, ensuring a consistent and comfortable temperature. Without it, the warm air would simply sit stagnant, rendering your heater ineffective.

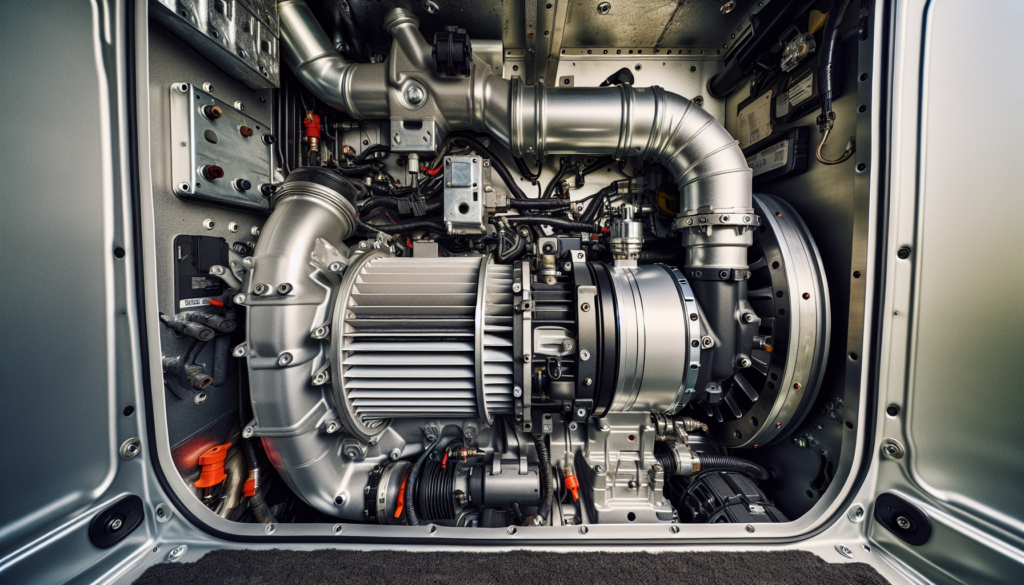

Components of a blower motor

A blower motor comprises mainly of the motor itself, the fan wheel, and a housing, wherein the wheel rotates. The motor itself uses electricity to generate a rotational movement. This motion is then transferred to the fan wheel, which propels the air. The housing contains and directs the flow of air through your vehicle’s HVAC system.

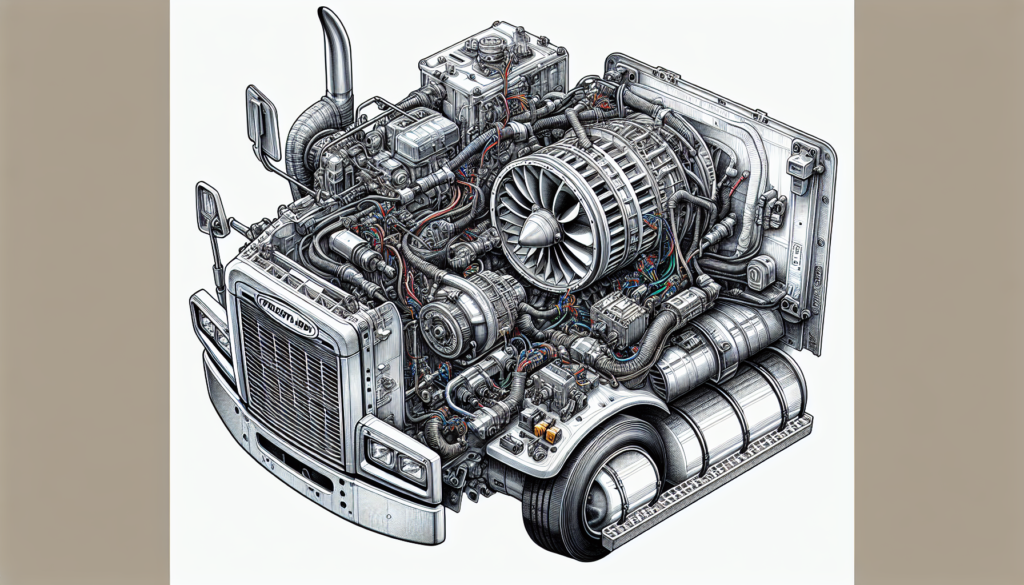

How blower motors work in Freightliner trucks

In a Freightliner truck, the operation of the blower motor is mostly identical to any other vehicle – it takes cool or warm air and circulates it through your cabin. However, Freightliner’s design and construction may vary in terms of placement, power, and accessibility. Thus, it’s essential to familiarize yourself with your specific model’s user manual or consult a professional when needed.

Symptoms of a Faulty Blower Motor

Identifying a faulty blower motor can prevent minor issues from escalating into more significant and costly repairs. Here are some signs you should keep an eye out for.

Lack of airflow from the heater vents

One of the most immediate and noticeable symptoms of a failing blower motor is a significant decrease in airflow from your heater vents. If you turn up the heat and still feel cold air blowing, or perhaps no air at all, it might be a sign that your blower motor is not functioning correctly.

Unusual noises during operation

Another sign of potential trouble is any unusual noise during the operation of your heater or air conditioner. If you hear a squeaking, humming, grinding, or other out-of-the-ordinary noises, it could be an indicator that your blower motor is under stress or failing.

Intermittent blower motor functionality

If your blower motor is functioning intermittently, it might indicate a fault. If it’s inconsistently blowing air, only works at certain speeds, or randomly stops altogether, you should have your system checked out.

Diagnosing Blower Motor Issues

Once you’ve identified the potential symptoms of a faulty blower motor, the next step is to diagnose the specific issue. Here are some methods to help you determine what might be going wrong.

Visual inspection for damage or blockages

One of the easiest and most accessible ways to diagnose a potential blower motor issue is through a visual inspection. Check for visible damage to the blower motor, debris, or blockage that can impede its operation.

Electrical testing for motor functionality

If a visual inspection doesn’t reveal anything, an electrical test might be necessary. Using a multimeter, you can check whether the motor is receiving the correct voltage. If not, this could point to a fault in the motor or the vehicle’s electrical system.

Assessing the blower motor resistor

The blower motor resistor is essential for controlling the speed of the fan, as it adjusts the current sent to the motor. If you notice that the fan runs at high speed only, or not at all, it could be an issue with this component.

Common Causes of Blower Motor Problems

There are several common causes of blower motor problems that you should be aware of. Knowing them can help prevent issues from arising in the first place.

Wear and tear over time

As with any mechanical component, wear and tear over time is inevitable. The components of your blower motor are not exempted from this fact and could wear out after extended use.

Electrical faults and wiring issues

As an electrical component, any malfunction in the wiring or overall electrical system can affect your blower motor. Shortages, loose cables, and blown fuses can all contribute to blower motor problems.

Debris and obstructions

Debris like dust, leaves, and even small critters can get into the blower motor and obstruct its functionality. Regular cleaning and inspections can go a long way in preventing these issues.

The Impact of Blower Motor Failure on Heating Efficiency

A failing blower motor can significantly impact your Freightliner’s heating efficiency, especially during colder months when a consistent and warm cabin temperature is essential.

Inability to circulate warm air

The most crucial impact of a failing blower motor is the inability to circulate warm air. Without the necessary force to push the warm air through the vents, your heater essentially becomes useless.

Fluctuating cabin temperatures

If your blower motor is not functioning correctly, it can lead to fluctuating cabin temperatures. This inconsistency can mean a less comfortable ride and increased energy usage as your system works overtime to compensate.

Compromised defrosting capability

A failing blower motor can compromise your vehicle’s defrosting capability. This can be particularly problematic, as a clear and defrosted windshield is crucial for safe driving.

Repair or Replace: Making the Right Decision

Deciding when to repair your blower motor and when to replace it entirely can be a tricky decision. Here are some factors to consider when making this decision.

When to repair your blower motor

Minor faults or blockages that can be easily fixed might only require a simple repair. If your blower motor is functioning but not at its best, a repair might be all it needs to get it back in good shape.

The cost-benefit analysis of replacement

Sometimes, the cost of constant repairs can overtake the cost of a new blower motor. In these cases, it might be more economical to replace your current motor with a new one.

Availability of replacement parts for Freightliner models

Freightliner models may have specific parts and components that aren’t readily available. Therefore, the decision to repair or replace might also hinge on the availability of necessary parts.

Steps for Replacing a Faulty Blower Motor

If it turns out that a replacement blower motor is needed, understanding the steps involved can be beneficial whether you plan on doing the job yourself or just want to understand the process.

Gathering the right tools and parts

Before you start the replacement, ensure that you’ve collected all the necessary tools and parts. This might include a new blower motor, a set of screwdrivers, a wrench, and possibly an electrical tester.

Removing the old blower motor

The exact process for removing your old blower motor will depend on your Freightliner model. Generally, you’ll have to disconnect the blower motor from the power supply, remove it from its housing, and detach it from the fan.

Installing the new blower motor

Once the old one is removed, you can install your new blower motor. Make sure it’s securely in place, then connect it to the power supply and the fan. Cross-check everything before turning your vehicle on to test the new motor.

Maintaining Your Freightliner’s Blower Motor

Maintaining your blower motor can prevent issues from arising and extend its life. Here are some actionable steps to ensure your blower motor stays in the best possible condition.

Regular cleaning and dust removal

Regular cleaning can prevent debris from accumulating and causing issues with your blower motor. Dust removal can help keep your blower motor’s operation smooth and efficient.

Lubrication of moving parts

Like any mechanical component, the parts of your blower motor need regular lubrication to function properly. Regular lubrication can reduce wear, improve efficiency, and prolong the motor’s life.

Routine electrical checks

Regular checks of your vehicle’s electrical system can ensure that your blower motor is receiving the necessary power. It can also help identify potential electrical issues before they become significant problems.

Advanced Troubleshooting Techniques

Even with regular maintenance, blower motor issues can arise. Thankfully, there are various advanced troubleshooting techniques that can help you identify and solve these issues.

Utilizing diagnostic software

Diagnostic software can help identify the root cause of your HVAC system’s malfunction. It can point you towards the source of the problem and help guide your repair process.

Understanding Freightliner’s HVAC codes

Understanding HVAC codes specific to your Freightliner model can also assist in identifying issues. These codes can indicate particular faults, helping you target your troubleshooting more effectively.

Engaging a professional mechanic for complex issues

When dealing with complex issues or if uncertainty remains despite your efforts, it might be time to consult a professional. Mechanics come equipped with expertise and equipment that can help diagnose and solve even the trickiest blower motor issues.

Professional Service vs. DIY for HVAC Issues

Whether to opt for professional service or DIY fixes for HVAC issues is an individual choice. It can depend on your comfort with mechanics, available time, and the complexity of the issue at hand.

When to seek professional help

If the problem’s complexity exceeds your confidence or abilities, or if you lack the necessary tools, professional help is advisable. Also, if the issue remains unresolved despite your efforts, you might need the help of a certified mechanic.

Benefits of DIY maintenance

On the other hand, DIY fixes come with the satisfaction of solving the problem yourself. It can also save you money and give you a deeper understanding of your vehicle’s workings.

Limitations of self-service in complex systems

While DIY maintenance can be beneficial, it does have its limitations. Some issues may simply be too complex to handle without specialized training or tools. In these cases, professional help is not only beneficial but necessary.

Your Freightliner’s blower motor is a pivotal component in maintaining a comfortable vehicle temperature. Understanding how it functions, recognizing symptoms of potential faults, maintaining it, and knowing when to consult a professional can all prolong its life and ensure its efficiency. These steps will make sure that you stay comfortable on the road, no matter what the weather outside is like.