You’re about to embark on a journey of understanding – unlocking the nitty-gritty of your Cascadia’s A/C system. This article will serve as your trusted guide on how to check the expansion valve, a vital part of your air conditioning system that plays a crucial role in cooling your vehicle. Let’s arm you with the knowledge and confidence needed to ensure your A/C operates at its peak, guaranteeing comfortable journeys every time. It’s simpler than you think, so let’s march forward.

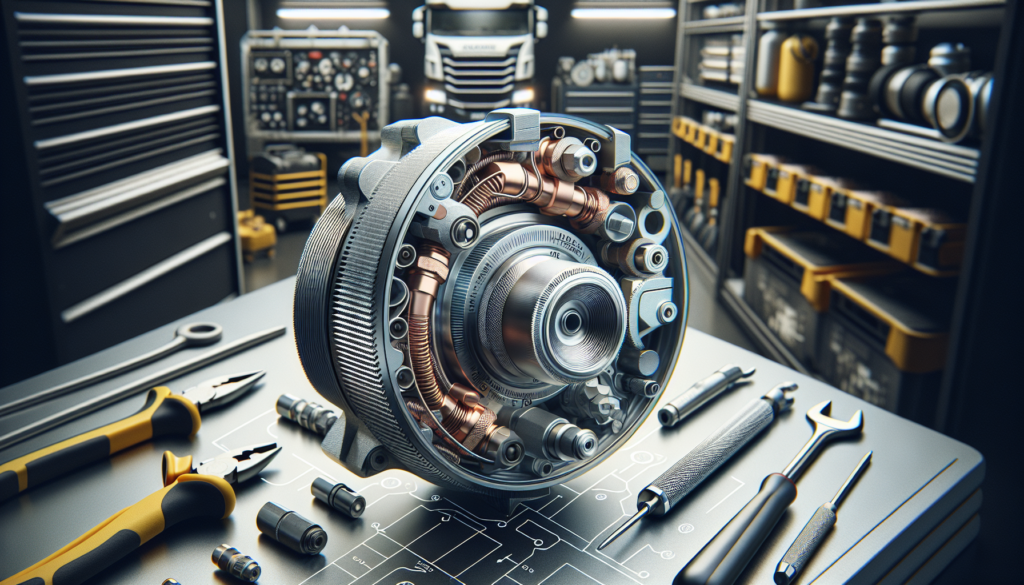

This image is property of images.pexels.com.

1. Overview of the expansion valve

When it comes to maintaining the comfort and temperature inside your vehicle, especially during those unbearably hot summer days, the expansion valve plays a crucial role.

1.1 What is the expansion valve?

The expansion valve, mostly found in an automotive Air Conditioning (A/C) system, is a little piece of hardware that controls the amount of refrigerant flow into the evaporator. Its primary function is to remove heat from your vehicle’s interior and expel it outside. It can be viewed as the heart of your A/C system, making sure the process of cooling is carried out efficiently.

1.2 How does the expansion valve work?

The expansion valve works by converting high-pressure and high-temperature liquid refrigerant from the condenser into a low-temperature and low-pressure mixture. As the refrigerant flows through the valve, it rapidly expands and cools. This low-temperature refrigerant is then able to absorb heat from the air in your vehicle effectively, resulting in a cooler environment for you.

2. Signs of a faulty expansion valve

Many things can be indicative of a malfunctioning expansion valve. Note these signs so that you’re able to spot trouble before it escalates.

2.1 Inadequate cooling

If your A/C isn’t cooling your car like it used to, a faulty expansion valve may be the culprit. It may mean the valve is not regulating the refrigerant flow properly, resulting in less effective cooling.

2.2 Frost or ice on the evaporator

Another telltale sign of a faulty expansion valve is frost or ice on the evaporator. This happens when the valve is stuck open, allowing too much refrigerant into the evaporator and causing freezing temperatures.

2.3 High-pressure readings

If your A/C system’s pressure readings are unusually high, it can signal an issue with the expansion valve. This could mean the valve is not opening enough, causing a build-up of pressure in the system.

2.4 Low-pressure readings

On the flip side, a valve that is stuck open can lead to abnormally low-pressure readings. This is because too much refrigerant is being allowed to enter the evaporator, resulting in low pressure.

3. Preparing to check the expansion valve

Before you inspect the expansion valve, ensure you are properly prepared.

3.1 Gathering necessary tools

For this task, you will need a few tools: safety glasses, gloves, a flashlight, a multimeter, and temperature and pressure gauges.

3.2 Ensuring safety precautions

Always prioritize your safety. Wear safety glasses and gloves and ensure you’re working in a well-ventilated area to prevent inhalation of harmful fumes.

3.3 Identifying the expansion valve location

The expansion valve is usually located on the low side of the A/C system, typically near the firewall. A repair manual can be handy to accurately locate it.

4. Checking the expansion valve visually

To make sure your expansion valve is in a good working state, start by visually inspecting it.

4.1 Inspecting for physical damage

First, look for signs of physical damage such as cracks or breakages. If you spot any, it’s time to replace the valve.

4.2 Checking for clogs or debris

Clogs or debris within the valve can affect its operation. Use your flashlight to check for any visible obstruction.

4.3 Verifying proper valve seating

The valve should sit correctly in its location. If you notice it is out of place or not seated right, it may not function correctly.

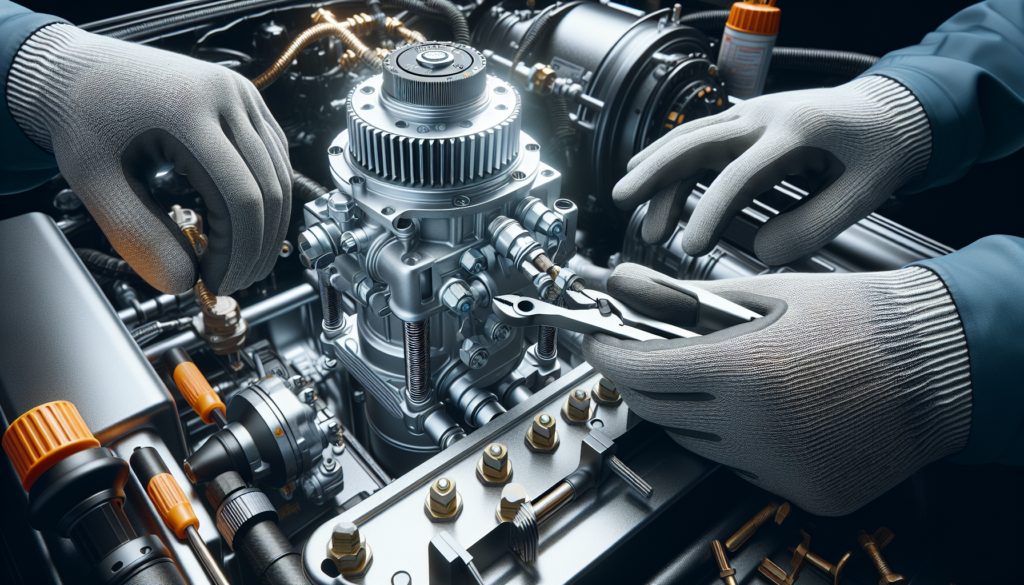

This image is property of images.pexels.com.

5. Testing the expansion valve with a multimeter

You can use a multimeter to determine if there’s an electrical fault with the valve.

5.1 Disconnecting the electrical connector

Start by disconnecting the electrical connector from the expansion valve. Make sure the power is off before doing this.

5.2 Setting the multimeter to resistance mode

Next, set your multimeter to resistance mode. This will let you check the resistance levels of the valve, which can indicate if there are faulty connections.

5.3 Probing the connector terminals

Now comes the probing part. Insert the probes of your multimeter into the connector terminals. If the readings show a resistance value of around 30 to 40 Ohms, your valve is functioning correctly. Otherwise, it might suggest an electrical problem.

6. Assessing the expansion valve superheat

Superheat is an essential factor in evaluating the performance of your expansion valve.

6.1 Understanding superheat

Superheat refers to the extra heating of refrigerant gas above its boiling point in the evaporator. This ensures that only gas, not liquid, returns to the compressor, preventing damage caused by liquid slugs.

6.2 Measuring the suction line temperature

Use a temperature gauge to measure the temperature of the suction line leaving the evaporator. This gives you the superheated refrigerant temperature.

6.3 Calculating the superheat value

Observe the low-pressure gauge on your A/C system and note the pressure reading. Then, convert this pressure to temperature using a PT chart. Subtracting this from the temperature reading from the suction line will give you the superheat value.

This image is property of images.pexels.com.

7. Evaluating the expansion valve subcooling

Subcooling assessments can aid in identifying expansion valve inefficiencies.

7.1 Understanding subcooling

Subcooling refers to the temperature decrease of the refrigerant below its condensation temperature, a vital aspect of how an A/C system and the expansion valve function.

7.2 Measuring the liquid line temperature

Use a temperature gauge to record the liquid line temperature as the refrigerant leaves the condenser and before it arrives at the expansion valve.

7.3 Calculating the subcooling value

Note the high-pressure gauge reading, and convert this pressure reading to temperature using a PT chart. Subtract the liquid line temperature from this, and you have your subcooling value.

8. Checking for proper refrigerant flow

Assessing the refrigerant flow will verify the expansion valve’s performance.

8.1 Observing the evaporator and condenser

Monitor the evaporator and the condenser. They should not be too cold or too hot, as this could be an indication of inadequate refrigerant flow.

8.2 Assessing the refrigerant pressures

Evaluate the system’s high and low-pressure readings. An imbalance may indicate that the expansion valve isn’t effectively controlling the flow of the refrigerant.

8.3 Verifying temperature differentials

Temporarily touch the inlets and outlets at the expansion valve, and there should be a noticeable difference in temperature. If not, the refrigerant flow isn’t being properly controlled.

9. Cleaning or replacing the expansion valve

After evaluating the expansion valve, the next step might involve cleaning or replacing it.

9.1 Flushing the system

Flushing the system can help remove any clogs or debris, which may be affecting the operation of the expansion valve.

9.2 Removing and cleaning the expansion valve

If you still have issues, you may need to remove and clean the valve. Use a specialised cleaning agent and a soft cloth, but if the valve is beyond repair, it’s time to replace it.

9.3 Installing a new expansion valve

When installing a new expansion valve, ensure it is securely seated and there are no leaks from the connections. Reconnect any electrical connectors, replace any insulation, and reassemble any components you may have removed.

10. Testing the A/C system after expansion valve maintenance

After maintenance, always test your A/C system and check the performance of the expansion valve.

10.1 Recharging the refrigerant

Recharge the system with the right amount of refrigerant as specified by your vehicle’s manufacturer.

10.2 Checking for proper cooling

Turn on your A/C and see if it adequately cools your vehicle.

10.3 Verifying pressure and temperature values

Finally, double-check your pressure and temperature readings. Ensure that they are within the normal ranges, indicating your expansion valve is functioning optimally.

Remember, maintaining your vehicle’s A/C system helps sustain a comfortable and enjoyable driving experience. Regularly checking your expansion valve ensures your A/C delivers the cooling performance you need for those hot summer days. It’s not just about comfort but also about maintaining the overall efficiency and longevity of your vehicle’s A/C system.