Are you having trouble with the air conditioning system of your Freightliner Cascadia and suspecting a potential airflow issue in the condenser? The purpose of this article is to guide you fluently through the step-by-step process for diagnosing such problems. You will acquire the know-how to identify blockages, locate leaks, clean the condenser, and do a comprehensive system check, thereby ensuring the optimum performance of your A/C system.

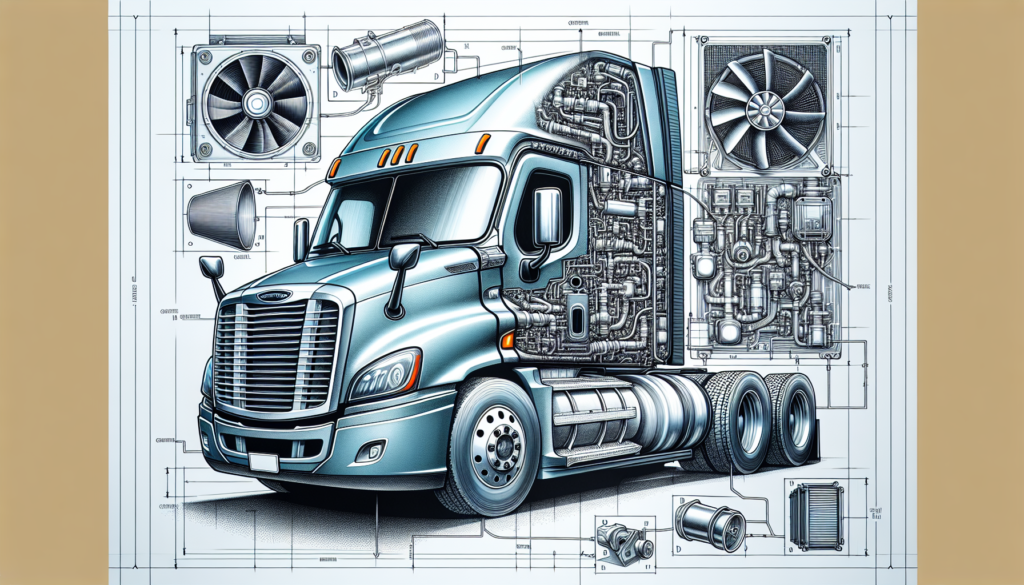

Understanding Freightliner Cascadia A/C System

Whether you’re a professional truck driver or a proud owner of the Freightliner Cascadia, it’s essential to understand the workings of its A/C system. Your comfort during long drives, particularly in hot weather, heavily depends on the efficiency of the A/C system. Let’s break down its key components and how they function.

Components of the A/C System

The A/C system of the Freightliner Cascadia is composed of several key components. This includes the compressor, condenser, expansion valve, and evaporator. Each component plays a critical role in ensuring the A/C system functions appropriately.

Function of the Condenser in an A/C System

The condenser in the A/C system outlet for heat collected inside the vehicle. As the cooling refrigerant enters the condenser, it transforms from a high-pressure gas into a high-pressure liquid due to the release of heat. Therefore, it plays a pivotal role in maintaining the optimal cooling efficiency of the A/C system.

Understanding the Airflow Mechanism

The airflow mechanism in the A/C system facilitates the transition of the refrigerant between phases. Proper airflow through the condenser is critical for this process. If airflow is obstructed for any reason, such as dirt, dust, or physical damage, the condenser’s efficiency can significantly decline.

Identifying Symptoms of Airflow Issues in the Condenser

Encountering airflow issues within the condenser part of your A/C system can give rise to a variety of symptoms. Recognizing these early signs can help you diagnose and address them before they escalate.

Reduced Cooling Efficiency

If you notice your A/C isn’t as effective as usual, it could indicate airflow issues within the condenser. As mentioned earlier, proper airflow is integral for the refrigerant’s phase transition and overall system cooling efficiency.

Unusual Noises

Airflow issues can also manifest through unusual noises emitting from your A/C system. Should you hear hissing, rattling, or general noise coming from the A/C, it might be due to improper airflow in the condenser.

Increased Humidity Inside the Truck

Condensers are essential for regulating humidity levels inside the truck. Therefore, if you experience an unusual increase in humidity, it might be due to a malfunctioning condenser that requires attention.

Tools Required for Diagnosing Airflow Issues

To further investigate possible airflow issues, there are a few handy tools that will help with the diagnosis

Airflow Meter

An airflow meter measures the amount of air reaching the condenser. A significant drop in airflow can indicate potential issues that require further exploration.

Thermometer

A thermometer can help evaluate the cooling capacity of the A/C system. By monitoring temperature levels, you can identify inconsistencies that might indicate airflow issues in the system.

Air Conditioning Test Gauge

Usually used by professionals, an air conditioning test gauge supplies precious information on the A/C system’s pressure levels, which can help identify possible malfunctioning areas.

Flashlight

A simple flashlight can be a useful tool. It will help you conduct a detailed visual inspection of the A/C system, particularly, the condenser.

Safety Measures Before Diagnosing Airflow Issues

Care must be taken when investigating and diagnosing issues, especially coupled with potential electrical hazards.

Mandatory Use of Safety Gears

Always wear safety gear, including protective eyewear and gloves. They’ll shield you from possible accidents during the inspection or repair process.

Disconnecting the Truck from Any Power Source

Before starting any diagnosis, disconnect the truck from all power sources to eliminate the risk of electrocution.

Ensuring the A/C System is Off

Also, make sure the A/C system is switched off before starting your inspection. This will help prevent any accidents and protect the A/C system’s integrity

This image is property of images.pexels.com.

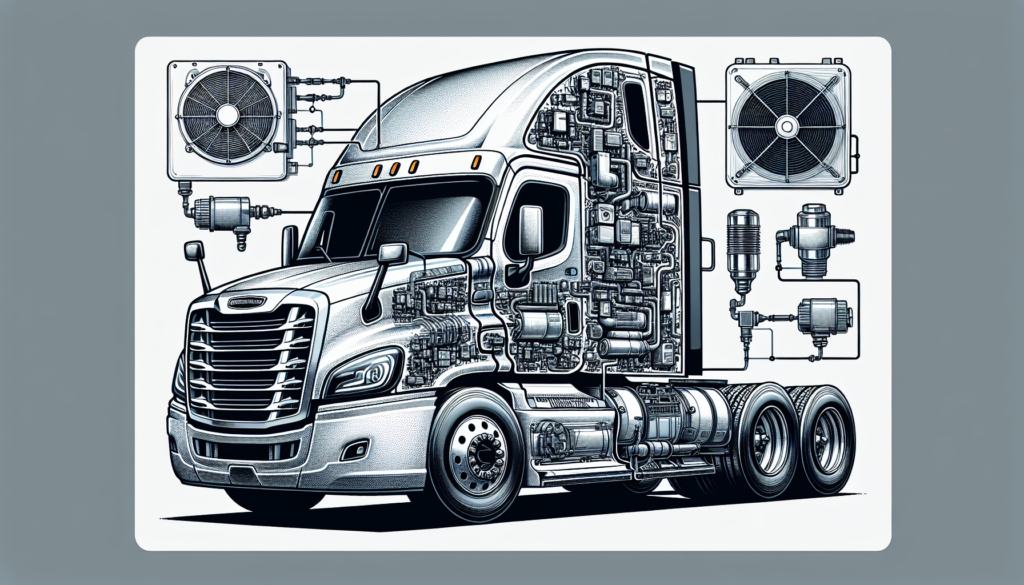

Physical Inspection of the Condenser

Performing a physical inspection of the condenser is crucial in diagnosing airflow issues.

Checking for Physical Damages

Begin by assessing the condenser for any visible damage. A damaged condenser can often impede optimal airflow, leading to inefficient cooling.

Inspection for Any Blockages

Inspect the condenser for blockages, such as dust, dirt, or debris. These can obstruct airflow and reduce the A/C system’s efficiency.

Checking the Positioning of the Condenser

Lastly, make sure the condenser is correctly positioned. A misaligned condenser may not function all that effectively, which might contribute to airflow problems.

Checking the Flow of Refrigerant

Another crucial element in diagnosing airflow issues involves inspecting the refrigerant flow.

Assessing Refrigerant Levels

Use your air conditioning test gauge to measure the current refrigerant levels. Low refrigerant levels can often hinder optimal airflow and affect your A/C system’s cooling efficiency.

Checking for any Leaks

While assessing refrigerant levels, keep an eye out for any potential leaks. Leaks are detrimental to the function of the A/C system, and they’ll cause reduced refrigerant levels.

Observing Refrigerant Flow

Observe the refrigerant flow carefully. Irregularities in its flow may suggest potential airflow problems that could impact the A/C’s cooling capacity.

This image is property of images.pexels.com.

Temperature and Pressure Checks

Temperature and pressure checks are also crucial in diagnosing airflow issues in your Freightliner Cascadia’s A/C system.

Measuring the Temperature Differences

Measure the temperature of the air entering and leaving the condenser using a thermometer. Significant disparities might indicate airflow issues.

Assessing the Pressure Levels

Next, use an A/C test gauge to check the pressure in the system. Fluctuations or low pressure can sometimes point towards airflow problems.

Identifying Anomalies in Temperature and Pressure Readings

Keep a close check on both the temperature and pressure readings. Any anomalies in these values can potentially suggest issues with airflow in the system.

Checking the Condenser Fan

The condenser fan is another critical component to consider when diagnosing airflow issues.

Observed Speed of the Fan

Check the fan’s speed to ensure it’s operating at its optimal capacity. A slow-moving fan might hinder the airflow process.

Physical Condition of the Fan Blades

Inspect the physical condition of the fan blades for any signs of wear or tear. Damaged blades may disrupt airflow within the A/C system.

Noise Level of the Fan

Lastly, listen carefully to the fan’s noise level. Unusual sounds might indicate potential issues that could be affecting the system’s airflow.

Assessing the A/C System After Initial Diagnosis

Finally, after completing the initial analysis, it’s important to assess the A/C system’s overall performance.

Comparing Pre and Post Diagnosis Performance

Compare the performance of the A/C system before and after your diagnosis. If there’s a noticeable improvement, your efforts have likely paid off.

Identifying the Need for Professional Assistance

However, if problems persist, don’t hesitate to call in professional assistance. Dealing with airflow issues can sometimes get complex, and an expert’s touch might be needed.

Understanding the Severity of the Airflow Issue

With careful inspection and analysis, you should have a better understanding of the issue’s severity. Not all airflow problems are equal, and knowing the exact nature of your problem can help in devising an effective solution.

Maintenance to Prevent Future Airflow Issues

After troubleshooting, regular maintenance can go a long way in preventing future airflow issues and prolonging the life of your A/C system.

Scheduled Inspection and Maintenance

Regular inspection and maintenance can help you steer clear of potential airflow problems. It allows you to identify and address minor issues before they become major ones.

Keeping the Condenser Clean

Always keep the condenser clean to ensure unrestricted airflow. A clean condenser can function more efficiently and last longer.

Regular Top-Up of Refrigerant

Regularly topping up the refrigerant in your A/C system can help maintain optimal airflow and cooling efficiency.

Prompt Attention to Minor Issues

Pay prompt attention to minor issues before they escalate. Issues like irregular noises, reduced cooling efficiency, and slight temperature and pressure fluctuations may be indicating a bigger problem.

With an understanding of the Freightliner Cascadia A/C system’s components and a few handy tools, you’re well equipped to maintain the performance of your vehicle’s A/C system. Be proactive, thorough, and mindful of safety measures to ensure the longevity and efficiency of your A/C system.