Your Freightliner’s air conditioning compressor is a hard-working component that ensures your comfort during those long hauls. When it performs optimally, it’s easy to forget about it; but just like any other part of your truck, it demands regular maintenance. This article is going to provide a comprehensive guide on the steps you need to take to keep this essential machine running smoothly. From basic routine checks to more detailed inspections, here’s everything you’ll need to keep your Freightliner’s air conditioning compressor in peak condition.

Understanding the role of an Air Conditioning Compressor

Having a functioning air conditioning system in your Freightliner, or any other vehicle for that matter, makes for a pleasant driving experience. And at the heart of every air conditioning system lies an integral component: the compressor. Understanding its role can help you grasp the importance of maintaining it and ensure your comfort on the go.

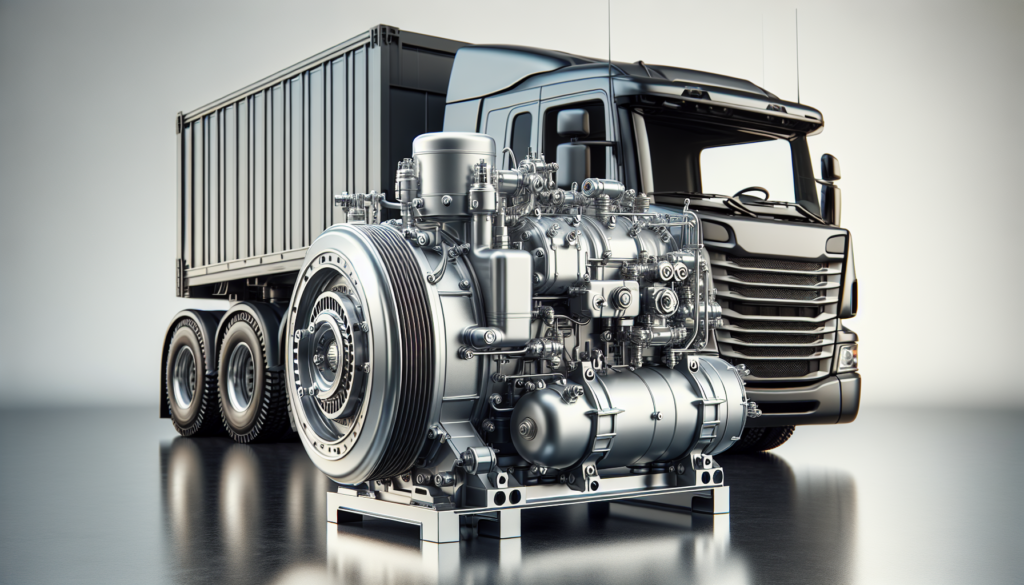

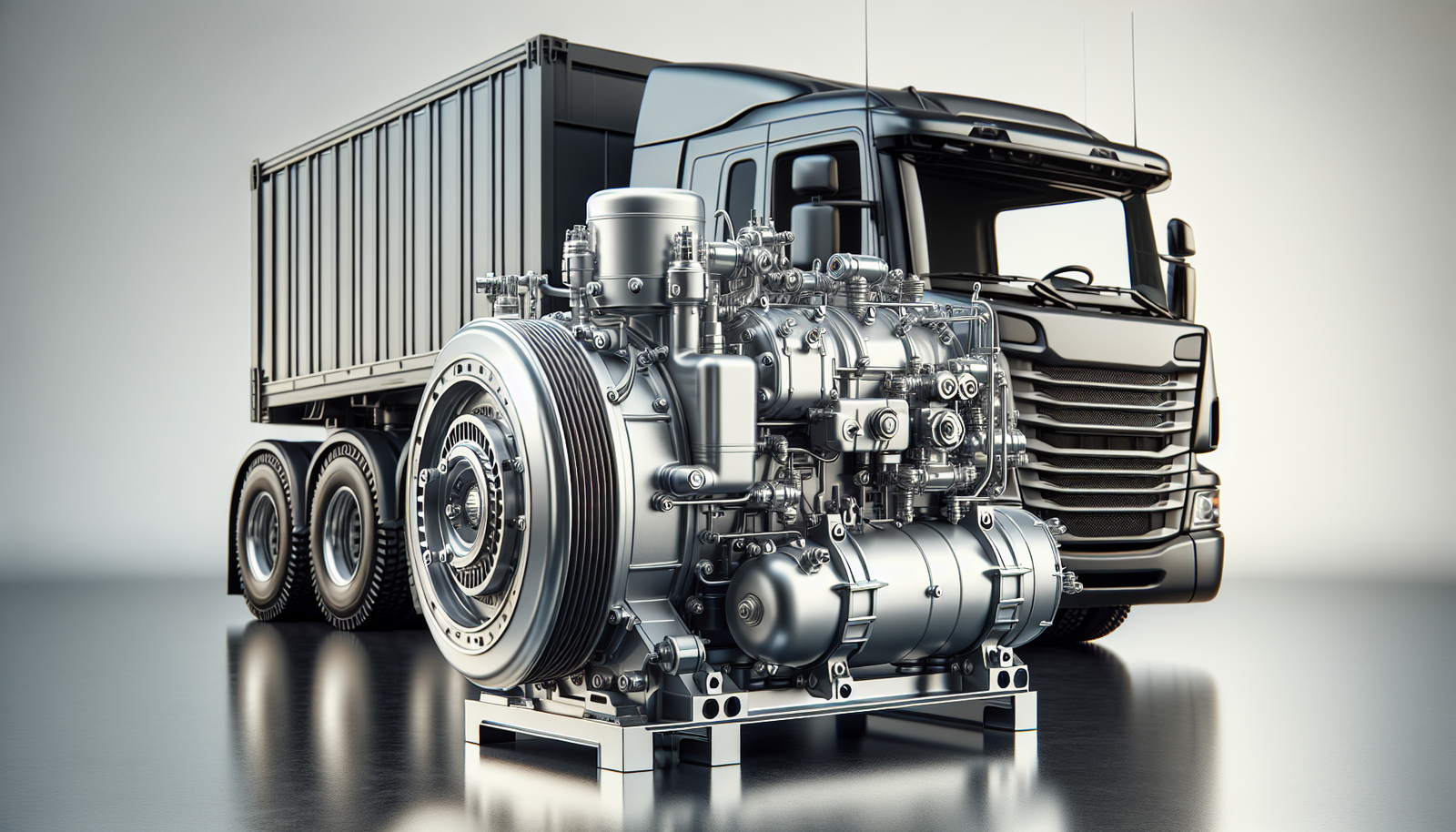

Defining the AC compressor in a Freightliner

The air conditioning compressor is a device in your Freightliner’s cooling system. It functions similarly to a small motor, with pistons that compress the refrigerant and circulate it through the system. You can find it in the engine bay of your truck, where it works in tandem with other components of the cooling system to regulate temperature and keep you comfortable.

Understanding compressor’s primary function in the cooling system

The AC compressor has a primary role: to compress and circulate coolant throughout the AC system. It kicks into action when you turn on your vehicle’s air conditioning. The compressor draws in low-pressure refrigerant gas from the interior of the truck, compresses it into a high-pressure, high-temperature gas and send it to the condenser. This cycle ensures cool air is continually dispersed throughout the cabin of your Freightliner.

Explaining the importance of regular maintenance for AC compressors

Just like any other mechanical component, your air conditioning compressor requires regular maintenance to keep performing its job effectively. Failure to maintain it can lead to costly repairs or replacements down the line. Regular checks, cleanings, lubrication and, when required, timely repairs can ensure your AC compressor lasts for a long time.

The Importance of Regular Maintenance

Maintaining your AC compressor regularly is one of the most significant steps towards ensuring the durability and the efficient operation of your air conditioner.

Identifying key reasons for regular compressor maintenance

Regular compressor maintenance aids in detecting minor issues that can significantly evolve into major problems if left unresolved. Through this, you can prevent system failures and continue to enjoy comfortable temperatures throughout your journeys. It also aids in maintaining the energy efficiency of your AC, ensuring that it does not consume more energy than it should.

Understanding the impact of neglecting maintenance

Ignoring regular maintenance of your AC compressor can be costly. The compressor could fail completely, rendering your AC system non-functional. It could also affect the performance of other components in the AC system, consequently leading to a major system overhaul.

Discussing preventive maintenance

Preventive maintenance involves regular inspections, cleanings, and minor repairs when necessary to keep the compressor in optimal condition. Ideally, preventive maintenance should be performed by skilled professionals. This practice will not only prolong the compressor’s life but also save you from potentially high repair costs.

Regular Compressor Checks

Carrying out regular checks on your compressor is a part of the preventive maintenance process.

Explanation of the regular checks

Regular checks on your compressor mainly involve visual inspections. You are looking for any signs of damage such as leaks, abnormal noises, and signs of wear and tear on the belts driving the compressor.

Steps to perform regular checks on the compressor

Begin by identifying where the compressor is located in your Freightliner. Perform a visual inspection, looking for any leakages or worn-out seals. Listen to the compressor for any abnormal noises when the AC is turned on. Furthermore, check the drive belt for wear and tear, and ensure it is correctly tensioned.

Elaborating the ideal frequency for compressor checks

The ideal frequency for compressor checks can vary, but a good rule of thumb is to check it every time you get your oil changed. This way, it aligns with your regular service schedules, and hence it’s less likely that you will forget.

Common Issues in Compressor Maintenance

Just like any other part of your Freightliner, common issues may arise while maintaining your compressor. Being aware of what to look out for can save you time and money.

Highlighting common problems associated with compressor maintenance

Some common problems that might come up during compressor maintenance are leakage of refrigerant, compressor clutch failure, and blocked or clogged condenser. These issues can significantly affect the performance of your AC unit.

Explaining signs and symptoms of compressor failure

Compressor failure might manifest as reduced cooling efficiency, strange noises when the AC is running, hard starting, or the AC system not working at all. If you notice any of these symptoms, it’s time to have your compressor checked by a professional.

Understanding the complications arising from ignoring common maintenance issues

Neglecting maintenance issues not only leads to compressor failure but could also potentially damage other components of the AC system. This could escalate your repair costs significantly, leading to expensive replacements.

Expert Maintenance Services

When it comes to compressor maintenance, it’s often recommended to lean on professional expertise.

Choosing professional maintenance services

Professional maintenance services have trained technicians who can effectively and efficiently inspect, diagnose, and repair any issues with your AC compressor. Because of their experience and expertise, they can also provide you with valuable advice to maintain your compressor in optimal condition.

Explaining benefits of engaging experts for compressor maintenance

Engaging experts for compressor maintenance ensures that the task is carried out to the highest standard. They possess the right tools and knowledge to perform the task efficiently. They can identify issues that you might overlook, thereby preventing minor issues from escalating into major ones.

Making a case for long-term maintenance contracts

Opting for long-term maintenance contracts with professional services can save you from the bother of frequent checkups. These contracts often involve regular maintenance checks and minor repairs for a specified period. Additionally, these can turn out to be cost-effective in the long run.

Cleaning the Air Conditioning Compressor

As part of your compressor’s maintenance, cleaning plays a crucial role.

Providing a step-by-step guide on cleaning the compressor

To clean your AC’s compressor, start by turning off your vehicle and disconnecting the battery. Remove any visible dirt and debris from the exterior of the compressor using a brush. Follow this by spraying a commercial compressor cleaner, allowing it to sit for a few minutes and then rinsing it off using a hose. Remember to protect any electrical connections during this process.

Discussing the importance of cleaning for compressor performance

Regular cleaning of your AC’s compressor can lead to improved performance. It aids in better heat dissipation, takes off undue stress from the unit, and helps in more efficient functioning.

Emphasizing on the right cleaning materials and tools

Using the right cleaning materials and tools is vital for the safe and effective cleaning of your compressor and also prevents potential damage. A soft brush, commercial compressor cleaner, air blower, and protective gear like gloves and eye protection are a few essentials.

Oil Changes for the Compressor

Just like your vehicle needs oil changes, so does your AC compressor for smooth operation.

The importance of changing compressor oil regularly

Changing the compressor oil is important as it helps in lubricating the compressor, ensuring that it runs smooth and eliminates overheating.

Steps to safely change the compressor oil

To start, ensure your vehicle is off and cool. Locate the compressor and remove the front plate to reveal the oil reservoir. Extract the old oil, replace it with new compressor oil, and securely reinstall the reservoir cap. Ensure you dispose of the old oil correctly, following local disposal guidelines.

Suggestions on the best oil types for compressors in Freightliners

When it comes to choosing oil for your compressor, opting for a synthetic blend often proves to be a good choice. Synthetic oil tends to be more resilient to heat and can provide better lubrication, leading to prolonged compressor life.

Replacement of Compressor Parts

Occasionally, maintaining your compressor might mean replacing some parts.

Understanding when replacement is necessary

Replacement of compressor parts is necessary when they show signs of severe wear and tear or aren’t functioning optimally even after maintenance. A professional inspection can help determine if replacements are needed.

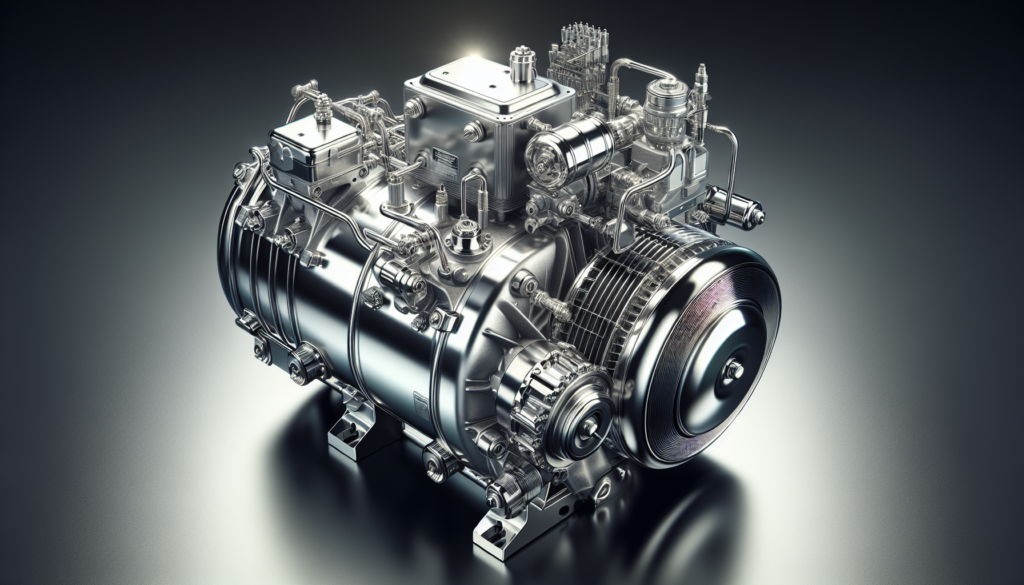

Introduction to various compressor parts and their lifespan

Major compressor components include the AC clutch, belts, seals, and oil reservoir. While the lifespan of these parts can vary significantly, regular maintenance can help extend their serviceability.

Guidelines on how to replace compressor parts

Replacing compressor parts needs care, precision and at times, special tools. It’s best to refer to your Freightliner’s manual for specific guidelines or engage a professional to ensure parts are replaced accurately and safely.

Safety Measures in Compressor Maintenance

Working with an AC compressor, like any other motor machinery, requires a certain level of precaution.

Highlighting safety measures during compressor maintenance

Safety measures include ensuring the truck’s engine is off when conducting maintenance, using the correct tools and safety equipment, and observing caution when working with coolant due to its high-pressure nature.

Explaining how to handle compressor-related emergencies

Should a compressor-related emergency arises, it’s essential to take steps to safeguard both you and your vehicle. If possible, turn off the engine and disconnect the battery to avoid any electrical mishaps. Always consult with a professional if you’re uncertain or uncomfortable handling the situation yourself.

Tips for safe compressor maintenance practices

Regularly maintaining and cleaning your space, using the correct tools for the job, observing safety etiquette and avoiding hurried repairs can contribute significantly to safe compressor maintenance practices.

Maintaining Other Components of the AC System

Compressor maintenance lies in sync with the upkeep of other AC components.

Explaining maintenance requirements of other AC system components

The well-being of your AC system also depends on the health of the condenser, evaporator, and air filters. Regular cleaning, inspection, and timely replacements can keep the entire unit running smoothly.

Recognizing the relationship between the compressor maintenance and overall AC system

The compressor, being a key component, affects the performance of the entire AC system. Thus, regular compressor maintenance can reflect positively on the health and efficiency of the whole system.

Sharing maintenance routines for harmonious operation of the entire AC system

A well-coordinated maintenance routine involving the compressor, condenser, evaporator, and filters can ensure harmonious operation of your AC. This includes regular checkups, oil changes, part replacement when necessary, and professional service.

Remember, regular maintenance is an investment in the longevity and efficiency of your Freightliner’s air conditioning system. Embrace it as part of your routine and you will not only get years of comfort but also keep potential costly repairs at bay.