Imagine you’re setting out on a long haul in your trusty Cascadia, ready to conquer the miles ahead. Comfort is your co-pilot, and nothing says comfort like a well-functioning A/C system. But what happens when your cabin doesn’t stay cool or your vents fail to push out that refreshing air? It could be a sign that your blower motor is calling for a replacement. In the article “How Can You Tell If The Blower Motor In A Cascadia’s A/C System Needs Replacement?”, you’ll discover the telltale signs that your blower motor might be on the fritz—from weak airflow and odd noises to no air coming from the vents—ensuring that your drive is as pleasant and chilled as intended, no matter the weather outside.

Understanding the Cascadia’s Blower Motor

Function of the Blower Motor in A/C Systems

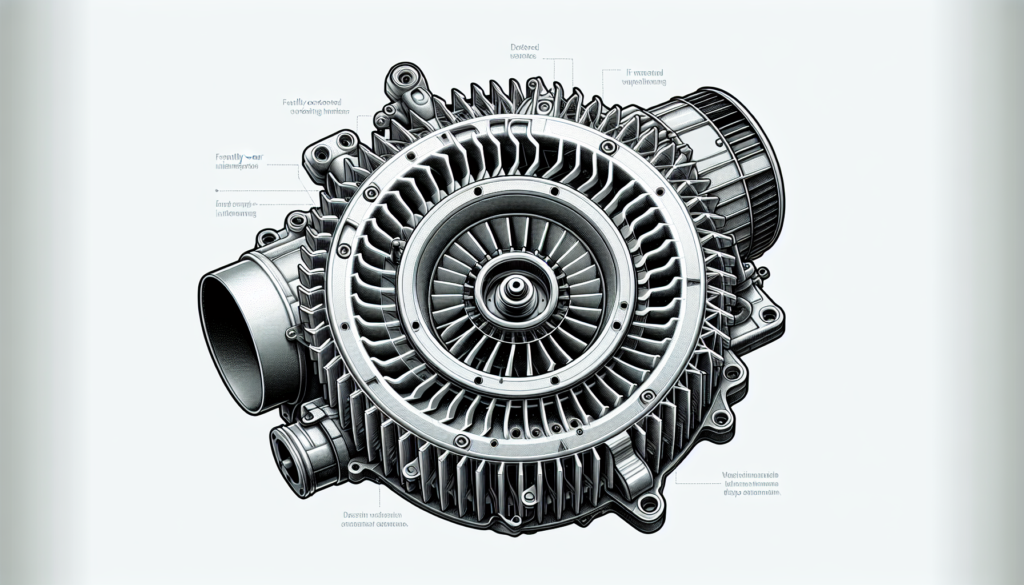

Your Cascadia’s A/C system is integral to your comfort on long hauls. The blower motor is a key component—it’s responsible for pushing air through the vehicle’s HVAC (Heating, Ventilation, and Air Conditioning) system. Imagine it as the heart of the A/C system, pumping cool air when you need a break from the heat. The blower moves air across the evaporator, which cools it before it enters the cabin, ensuring that your climate control is at your command.

Typical Lifespan of a Cascadia Blower Motor

The longevity of a blower motor in your Cascadia can vary. Typically, you can expect it to last for the life of the truck, but sometimes it might need replacement after about 5 to 7 years. Like other mechanical components, its lifespan is influenced by several factors, including usage patterns, maintenance, and environmental factors.

Common Cascadia Models and Their Blower Motors

There are several models of Cascadia trucks, and while they all share the same commitment to quality, some differences in their HVAC systems must be noted. The blower motors fitted might vary slightly in power, size, and design, tailored to the specific model and its cabin space requirements.

Signs of Blower Motor Failure

Weak Airflow from Vents

When you crank up the A/C, and the gust you expect is more of a feeble breeze, it could signify your blower motor is struggling. Reduced airflow often indicates that the motor isn’t operating at full capacity, which could be due to a variety of reasons, including a failing motor, blocked air passageways, or a compromised fan.

Unusual Noises When A/C is Running

Keep your ears open for any strange noises when the A/C system is on. Sounds such as rattling, banging, or whining can suggest that your blower motor is on the fritz. These noises might be caused by debris in the blower wheel or a motor that’s seen better days.

Intermittent Operation of the Blower

Does your blower motor have a mind of its own, working one minute and then taking an unannounced break the next? If the operation of the blower is inconsistent, it could point towards a motor that’s reaching the end of its road, or it could be dealing with an electrical issue.

No Airflow at All

If you’ve set your A/C to full blast and there’s zero airflow, the blower motor might have failed completely. It’s also possible that the issue isn’t the motor itself but rather a blown fuse or tripped circuit.

Electrical Issues and Trouble Codes

Understanding Cascadia’s Diagnostic Trouble Codes (DTCs)

Your Cascadia is smart. When there’s an issue with the truck’s A/C system, it can generate diagnostic trouble codes, or DTCs. These codes will alert you to specific issues that need your attention, including potential problems with the blower motor.

Electrical Checks for Blower Motor Function

Before you replace your blower motor, you should perform some electrical checks. This includes making sure the motor is receiving power and that all connections are secure. A multimeter can be used to ensure that voltage is reaching the motor. Checking the relevant fuses and relays is also essential; if one is blown, it might just be a simple fix.

Signs of Wiring or Fuse Problems

If the motor isn’t receiving power but the fuses and relays are in good shape, closely inspect the wiring. Look for signs of wear, tear, or any disconnections. Over time, wires can degrade, which could be the source of your woes.

Mechanical Health: Bearings and Bushings

Listening for Squeaks and Grinding Noises

If you hear squeaking or grinding when the blower motor is in use, it might be a sign that the bearings are worn out. Bearings allow the motor to rotate smoothly, and when they deteriorate, they cause friction and noise.

Checking for Blower Motor Vibration

A healthy blower motor should operate smoothly with minimal vibration. Feeling a distinct shimmy from the A/C system might indicate that the motor’s inner workings are off. These vibrations can hasten wear and tear and should be inspected promptly.

Physical Inspection of Motor Bearings and Bushings

A close inspection can sometimes reveal the issue with bearings and bushings. Signs of corrosion or excess play can indicate that it’s time for a replacement. Take care not to overlook this step, as it’s an important part of ensuring the motor’s longevity.

Air Quality and Filter Assessment

Impact of Clogged Filters on Blower Motor Performance

Your blower motor depends on a steady airflow, and clogged filters can restrict this. Over time, cabin air filters can become blocked by dirt and debris, leading to additional strain on the motor and reduced system efficiency.

How to Inspect and Replace the Cabin Air Filter

Inspecting and replacing the cabin air filter is a maintenance task you can easily tackle. Make sure to check the filter periodically and swap it out according to the recommended service intervals or whenever it looks dirty. A clean filter can improve air quality and prolong the health of your blower motor.

Correlation Between Air Quality and Motor Strain

Poor air quality doesn’t just affect you; it also increases the strain on your blower motor. The more contaminants it has to push through, the harder it has to work, which can accelerate wear and shorten the motor’s life.

Blower Motor Resistor Functionality

Role of the Blower Motor Resistor in Speed Regulation

The blower motor resistor is crucial for changing the speed of the blower. By offering resistance within the motor’s electrical circuit, it lets you adjust the airflow from a gentle stream to a powerful blast. Without it, you might find your A/C system stuck on one speed, or not working at all.

Symptoms of a Faulty Blower Motor Resistor

A primary symptom of a faulty blower motor resistor is the inability to change the fan speed. If your fan is stuck on high or low, it’s a telltale sign. Similarly, if certain settings don’t work, but others do, this could also point to an issue with the resistor.

Diagnosing and Testing Resistor Health

Testing the health of a blower motor resistor is a step often overlooked. It’s not complicated; a multimeter can measure the resistance across the resistor’s terminals. If the readings don’t match expected specifications, it’s time for a replacement.

A/C System Performance

Temperature Inconsistencies Indicative of Blower Issues

If your cabin temperature fluctuates unexpectedly, don’t rush to blame the thermostat. It could be a sign that the blower motor isn’t moving air consistently, which can cause hot spots or cold patches in the cabin.

Assessing the Overall Cooling Efficiency

When evaluating the performance of your A/C system, don’t forget to consider the blower motor. If the air isn’t moving effectively, even the coldest air won’t be distributed properly throughout the cabin.

How Blower Motor Issues Affect A/C Performance

A faulty blower motor can lead to ineffective A/C performance. Even if the rest of your system is in tip-top shape, a struggling blower motor can render it useless. Remember, efficient cooling relies on a team effort from all parts of the system.

Visual Inspection of the Blower Motor

Locating the Blower Motor in a Cascadia

To inspect the blower motor, you first need to know where to find it. In your Cascadia, the blower motor is typically located under the passenger side dashboard or behind the glove compartment. Consult your owner’s manual for the exact location.

Identifying Physical Damage or Wear

Once you’ve located the blower motor, visually inspect it for signs of damage or wear. Look for cracks, rust, or any other indication that it’s seen better days. Physical damage is a clear sign that the motor needs to be replaced.

Presence of Debris or Obstructions

Sometimes, the issue can be as simple as leaves or other debris causing an obstruction. Remove any foreign objects you see around the motor and check inside the blower wheel if possible, as these can hinder the motor’s operation and reduce airflow.

Professional Diagnostic Procedures

When to Consult a Certified Technician

If you’ve gone through these steps but are still uncertain about the condition of your blower motor, consult with a certified technician. They have the expertise and experience to diagnose and resolve complex issues that are not always apparent to the eye.

Advanced Diagnostic Tools and Methods

Professional mechanics use advanced tools that can accurately diagnose problems with your blower motor. From electrical system analyzers to precision airflow meters, these tools provide a more comprehensive diagnosis than what you can achieve with basic checks.

Interpreting Professional Diagnostic Results

Understanding the results from a professional diagnostic can be challenging. Trust your technician to guide you through the findings and suggest the best course of action. They can advise whether your blower motor is salvageable or if a replacement is the more cost-effective solution.

FAQ About Blower Motors in Cascadia Trucks

Can a Blower Motor be Repaired or Only Replaced?

A blower motor can sometimes be repaired, depending on the specific problem. However, if the motor is burnt out or has sustained significant damage, replacing it is usually the more reliable and efficient option.

How does Extreme Weather Affect Blower Motors?

Extreme weather can affect blower motors by causing additional stress and strain, particularly during periods of frequent use. High temperatures can expedite wear, while winter conditions can lead to overexertion if the motor is battling against cold-induced viscosity in the lubricants.

Are There Aftermarket Blower Motors That Outperform OEM Parts?

Yes, there are aftermarket blower motors that claim to outperform OEM (Original Equipment Manufacturer) parts. However, you should exercise caution and ensure that any aftermarket part meets or exceeds the specifications and quality of the OEM. Choosing reputable brands and consulting with professional mechanics can ensure you get the best replacement blower motor for your Cascadia.

By understanding the signs of a failing blower motor, performing regular inspections, and consulting professionals when needed, you’ll maintain the comfort and efficiency of your Cascadia’s A/C system. Always remember, a well-functioning blower motor is key to a cool and pleasant drive.