Imagine you’re on the road, cruising comfortably in your Freightliner Cascadia when the air suddenly turns stale, and your cab becomes a mobile sauna. This unpleasant scenario could very well be the result of a clogged evaporator—a common issue that truck drivers face, but often overlook. In the article “What Happens When A Freightliner Cascadia’s Evaporator Gets Clogged?” you’ll discover the cascade of effects that can arise from this issue, how it impacts your driving experience, and what you can do to fix it and get back to enjoying your journey in cool comfort.

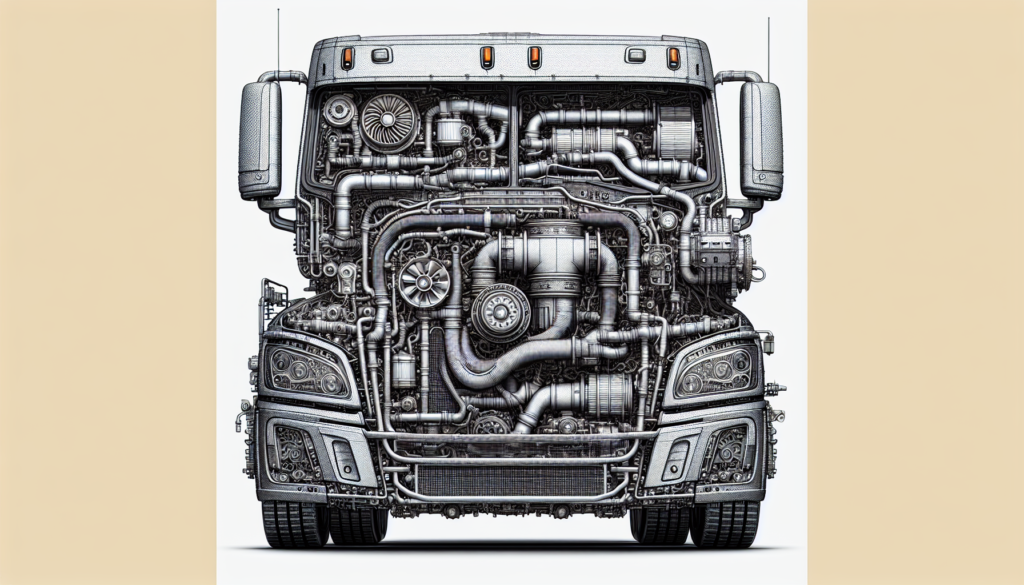

Overview of the Evaporator in Freightliner Cascadia

Function of the evaporator in the HVAC system

The evaporator in your Freightliner Cascadia’s HVAC system plays a crucial role in keeping you comfortable during those long hauls. Its primary function is to absorb heat from the air inside the cabin. The system drives air through the evaporator fins, and as the refrigerant within the evaporator absorbs heat, it changes from a liquid to a gaseous state, effectively cooling the air before it’s circulated back into the cabin. This process not only cools the air but also removes humidity, providing you with a comfortable environment no matter the weather outside.

Location and components of the evaporator

You’ll find the evaporator nestled within the dashboard of your Freightliner Cascadia, usually on the passenger side. It’s part of a larger assembly that includes components such as the blower motor and the heater core. The physical evaporator is made up of tubes and fins that facilitate the exchange of heat and allow for the condensation of moisture, which is then drained out of the system.

Common refrigerants used in the system

Your Freightliner’s HVAC system uses refrigerants – typically R-134a or the newer R-1234yf, which are known for their effectiveness and lower environmental impact. These substances are carefully regulated and need to be handled properly to maintain system health and adhere to environmental safety standards.

Signs of a Clogged Evaporator

Reduced cooling efficiency

When your evaporator starts to clog, one of the first signs you’ll notice is reduced cooling efficiency. The air coming from the vents might not be as cold as it used to be, or it might take significantly longer for your cabin to cool down to a comfortable temperature, leaving you sweating more than you’d prefer.

Unusual odors emanating from the vents

Have you caught a whiff of something foul coming from the vents? This could be a sign that mold or mildew is growing on your evaporator, which can happen when debris clogs the system and moisture can’t drain properly.

Poor airflow from the AC vents

If your blower is working hard but you’re only getting a weak flow of air from the vents, your evaporator could be clogged. The restricted air passage limits the amount of air that can pass through the system, resulting in poor performance of the air conditioning.

Visible signs of blockage on evaporator fins

If you take a peek at the evaporator fins and they’re covered in dirt or debris, it’s a sure sign of a clog. Physical blockages can severely hamper the system’s ability to exchange heat and cool the cabin efficiently.

This image is property of images.unsplash.com.

Causes of Evaporator Clogging

Accumulation of dirt and debris

One of the common causes of evaporator clogs is the accumulation of dirt, leaves, and other environmental debris. These can enter your HVAC system through the vents and get trapped, restricting air flow and system function.

Mold and bacteria growth

A moist environment like the evaporator is ripe for the growth of mold and bacteria. Over time, these can multiply and begin to obstruct the evaporator, leading to bad odors and potential health concerns.

Leakage of refrigerant and resulting contamination

Sometimes, the problem isn’t what’s getting into the system, but what might be leaking out. Refrigerant leaks can lead to contamination within the system, contributing to clogs and reduced cooling capability.

Consequences of a Clogged Evaporator

Increased strain on the HVAC system

A clogged evaporator makes the whole HVAC system work harder. This added strain can decrease its lifespan and lead to other components breaking down over time.

Potential compressor failure

Given that the compressor is like the heart of the HVAC system, increased strain from a clogged evaporator could lead to its failure. Replacing a compressor is costly, and it’s certainly something you’d want to avoid.

Negative impact on fuel efficiency

When the HVAC system works harder due to a clog, it draws more power from the engine, which can negatively impact your fuel efficiency. For you, this means more pit stops and higher fuel bills.

Compromised driver comfort and safety

A well-functioning HVAC system is not just a matter of comfort; it’s also a safety issue. In extreme temperatures, a clogged evaporator could compromise your ability to maintain a clear view through the windshield due to ineffective defogging, and that could be dangerous.

This image is property of images.unsplash.com.

Diagnosing a Clogged Evaporator

Visual inspection techniques

A visual inspection can often diagnose a clogged evaporator. If you’re comfortable accessing the evaporator, look for dirt and debris. Check for signs of refrigerant leakage, which will need to be addressed by a professional.

Utilizing diagnostic equipment

Specialized diagnostic equipment can help in detecting issues that aren’t visible to the naked eye. These tools can measure pressure levels and temperatures within the system to pinpoint problems like a clogged evaporator.

Assessing temperature differences

By measuring the temperature of the air before and after it passes through the evaporator, you can assess its efficiency. A significant difference in the expected cooling could indicate a clog.

Detecting unusual pressures in the system

Unusual pressure readings within the HVAC system might suggest a blockage. High pressure upstream of the evaporator combined with low pressure downstream is a telltale sign that something’s amiss.

Maintenance to Prevent Evaporator Clogging

Regular HVAC system checks

Keeping up with regular HVAC system checks ensures that minor issues can be detected before they become major problems. A professional technician can help you stay on top of this maintenance schedule.

Changing cabin air filters periodically

The cabin air filter is your first line of defense against contaminants entering the HVAC system. Changing it periodically can prevent a lot of potential clogs in your evaporator.

Ensuring proper refrigerant levels

Maintaining the correct amount of refrigerant in the system is vital. Too much or too little can cause issues, including clogs. This task is best left to professionals who have the correct tools and expertise.

Cleaning protocols for the evaporator

There are cleaning protocols and solutions designed specifically for evaporators. They can help to remove build-up and prevent the growth of mold and bacteria. Depending on your comfort level with vehicle maintenance, this might be a DIY task or something you leave to a trusted mechanic.

This image is property of images.unsplash.com.

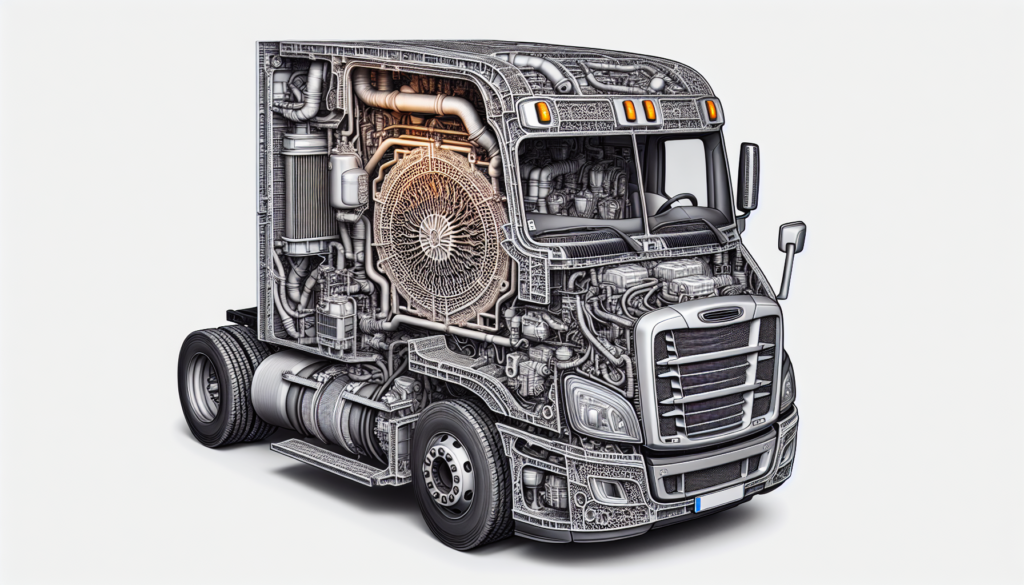

Repairing a Clogged Evaporator

Step-by-step cleaning process

If your evaporator needs a thorough cleaning, the process usually involves applying a specialized cleaning agent to break down the build-up, followed by a rinse to wash away the residue and debris. Care must be taken to avoid damage to the delicate fins.

Replacing damaged evaporator components

In some cases, when the evaporator is damaged or too clogged for cleaning, you may need to replace components. This task will likely require a skilled technician due to the complexity of the HVAC system.

Recharging the refrigerant in the system

If the evaporator or other parts of the system are repaired or replaced, the refrigerant will need to be recharged. This process involves evacuating the old refrigerant, vacuuming the system to remove moisture and contaminants, and filling with the correct amount of new refrigerant.

Testing the system post-repair

Once repairs are complete, it’s important to test the entire HVAC system to ensure that it’s functioning properly. This includes checking the temperature and airflow, as well as ensuring that the system is not leaking refrigerant.

Operational Practices to Avoid Clogging

Optimal usage patterns for the HVAC system

Using your HVAC system optimally can help prevent future clogs. This includes not running the AC or heat at maximum settings all the time and ensuring that you’re using the system in a way that promotes air circulation and moisture removal.

Minimizing contaminants entering the system

Be mindful of where you park and how you use your vehicle, as these can affect the amount of contaminants that enter the system. Parking in cleaner areas and avoiding driving in excessively dusty or dirty environments can help.

Advice on parking and storage of the vehicle

When parking or storing your Freightliner, consider using a cabin air purifier or moisture absorbers to keep the interior dry and minimize the risk of mold and mildew formation, which can lead to a clogged evaporator.

Technological Solutions for HVAC Maintenance

Overview of smart HVAC systems

The HVAC systems in newer models of freight vehicles, including the Freightliner Cascadia, are becoming increasingly sophisticated. Smart HVAC systems can automatically adjust to optimize performance and comfort, and they often include advanced filtration and monitoring technologies to keep the system running smoothly.

Benefits of using diagnostic software

With the advancement of onboard diagnostic software, troubleshooting HVAC issues has become more precise. This software can alert you to potential problems with the evaporator or other components before they become serious, allowing for preemptive maintenance.

Upgrades available for Freightliner Cascadia

Freightliner Cascadias can often be upgraded with the latest HVAC technologies. These upgrades can improve system reliability, reduce maintenance frequency, and even offer better fuel efficiency by optimizing the HVAC system’s operation.

Future Trends in Freightliner HVAC Systems

Innovations in evaporator design

Looking ahead, innovations in evaporator design promise to be more efficient, less prone to clogging, and easier to maintain. These designs might include materials that inherently resist mold and bacteria, or structures that discourage debris from becoming trapped.

Developments in environmentally friendly refrigerants

As environmental regulations become stricter, there’s a trend towards developing refrigerants that are less harmful to the atmosphere. This not only benefits the planet but also helps companies adhere to legislation while maintaining high-performance HVAC systems.

Predictive maintenance using AI and IoT

The future is bright with the promise of AI (Artificial Intelligence) and IoT (Internet of Things) paving the way for predictive maintenance. This technology can anticipate and inform when components like the evaporator are likely to require attention, potentially preventing clogs and other issues before they ever occur, keeping you cool and collected on the road.