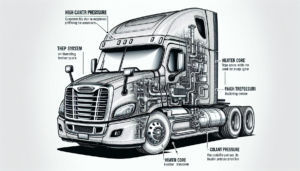

In the bustling world of big rig trucking, where the rhythm of the engine sets the pace of progress, maintaining an efficient cooling system is paramount. “Big Rig Cooling System Check: Ensuring Effective Engine Temperature Management” is your go-to guide for keeping your truck’s engine running smoothly through the scorching summer months. It shines a spotlight on the importance of regularly inspecting your radiator, hoses, and coolant levels, as well as the benefits of flushing and refilling your coolant to ensure optimal performance. With the right care, your big rig will keep powering through, mile after mile, without breaking a sweat.

Understanding Your Big Rig’s Cooling System

Maintaining the cooling system in your big rig is crucial for ensuring the engine operates efficiently, especially during the hot summer months. Let’s delve into the components of your cooling system and understand how it influences engine performance, along with spotting common signs of failure.

Components of the cooling system

Your cooling system is designed intricately to manage the engine’s temperature and includes several key components. The radiator, which acts as the core center for heat dissipation, the water pump that circulates coolant through the engine and radiator, thermostat which regulates the coolant flow based on temperature, and the hoses and belts that connect these parts together. Each piece plays a vital role in keeping your engine cool and running smoothly.

How the cooling system affects engine performance

The cooling system prevents your big rig’s engine from overheating and suffering damage. An efficiently working cooling system ensures that the engine maintains an optimal operating temperature, which is crucial for achieving good fuel efficiency and prolonging engine life. Conversely, an underperforming cooling system can lead to engine overheating, reduced power output, and, in severe cases, engine failure.

Common signs of cooling system failure

Be on the lookout for signs such as increased engine temperature readings, visible coolant leaks under your truck, steam coming from under the hood, and unexpected fluctuations in cabin heating. These symptoms could indicate a potential failure in the cooling system, prompting immediate attention to avoid more extensive damage to your engine.

Inspecting the Radiator

The radiator is key to your big rig’s cooling system. Regular inspections can prevent overheating and ensure your engine runs efficiently.

Checking for physical damage and corrosion

Inspect your radiator for any signs of physical damage, such as cracks or bends, and corrosion which might indicate a leak or weak spot in the system. Corrosion can significantly reduce the radiator’s efficiency and potentially lead to leaks.

Ensuring proper airflow

Make sure there’s nothing obstructing airflow to the radiator. Debris, like leaves or dirt, can block the radiator and reduce its cooling efficiency. Regular cleaning can maintain proper airflow and cooling performance.

Identifying leaks and blockages

Look for signs of coolant leaks around the radiator, which might appear as streaks or puddles under your truck. Blockages can also impede cooling efficiency, leading to overheating. Flushing the radiator can help remove these blockages.

Examining Radiator Hoses

Radiator hoses connect the radiator to the engine and play a crucial role in the cooling process. Regular inspections can ensure they are in good condition.

Looking for cracks, soft spots, and leaks

Inspect the hoses for any signs of wear, such as cracks, leaks, or soft spots. These issues can lead to coolant leaks and reduced cooling efficiency.

Checking hose clamps and connections

Ensure the hose clamps are tight and secure to prevent leaks. Also, check the connections for any signs of wear or damage.

Assessing wear and tear

Over time, hoses can deteriorate due to the extreme conditions they endure. Regularly assess them for wear and tear, and replace them as necessary to maintain optimal cooling performance.

Coolant Level and Quality Check

The coolant is vital for heat transfer in your big rig’s cooling system. Regular checks can prevent overheating and ensure your engine runs smoothly.

How to check coolant levels

Check the coolant level in the overflow tank and radiator (when it is cool) to ensure it’s within the recommended range. Low coolant levels could indicate a leak in the system.

Assessing the condition of the coolant

Inspect the coolant’s condition. It should be free of debris and not overly thick or discolored, which could indicate contamination or degradation.

The importance of using the correct type of coolant

Using the correct type of coolant is crucial for your big rig. Consult your truck’s manual to ensure you’re using the right coolant type and mixture to prevent corrosion and maintain cooling efficiency.

Coolant System Flushing and Refilling

Regular flushing and refilling of the coolant can prevent corrosion and freezing, ensuring your cooling system operates efficiently.

When to flush your cooling system

Most manufacturers recommend flushing the cooling system every 1-2 years. However, check your owner’s manual for specific recommendations for your big rig.

Step-by-step guide on flushing the system

To flush your cooling system, drain the old coolant, flush the system with a radiator flush solution or distilled water to remove deposits and corrosion, and then refill with new coolant. Ensure that you dispose of the old coolant properly, as it is toxic and harmful to the environment.

Proper coolant disposal methods

Dispose of the old coolant at a local recycling center or auto repair shop that accepts hazardous materials. Do not pour it down the drain or onto the ground.

Thermostat Check

The thermostat regulates the flow of coolant to maintain the engine’s optimal operating temperature.

Understanding the role of the thermostat

The thermostat opens to allow coolant flow when the engine reaches operating temperature and closes when it’s cool to speed up the warming process.

How to test your thermostat

To test your thermostat, start your engine and let it warm up. The upper radiator hose should start to feel warm once the thermostat opens. If it doesn’t, your thermostat may be faulty.

When to replace the thermostat

If your thermostat fails the warming test or if you notice your engine temperature gauge fluctuating widely, it might be time to replace the thermostat.

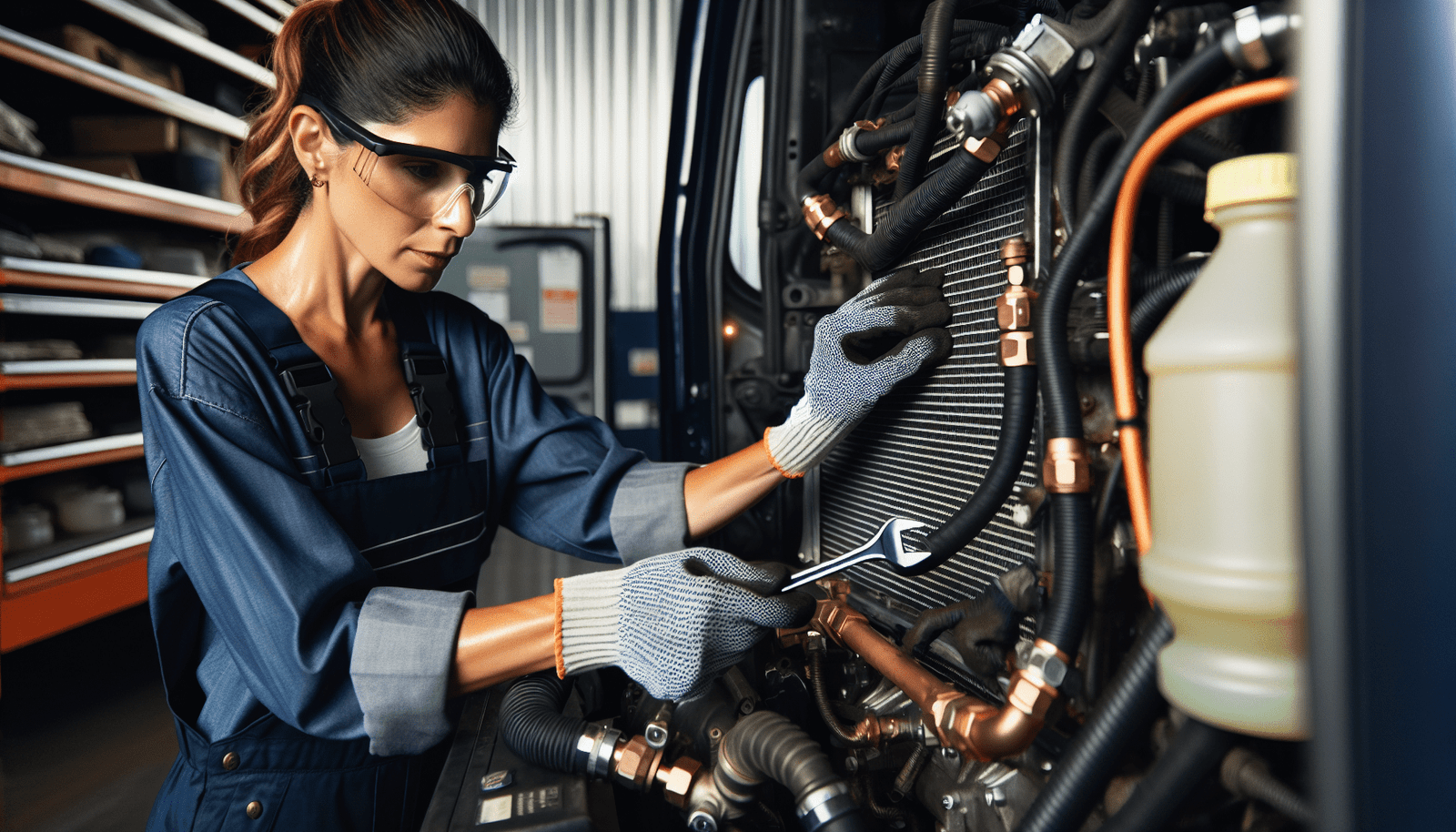

Water Pump Inspection

The water pump is essential for circulating coolant throughout the cooling system.

Signs of water pump failure

Watch for signs of coolant leaks near the water pump, overheating, or unusual noises from the pump area, indicating potential failure or malfunctions.

Checking for leaks and noises

Inspect the water pump for leaks regularly, particularly near the seals and gaskets. Listen for unusual noises that might indicate a failing pump.

The importance of water pump maintenance

Regular maintenance and early detection of issues with the water pump can prevent engine overheating and more significant damage.

Fan and Fan Clutch Assessment

The fan and fan clutch play vital roles in maintaining your big rig’s engine temperature.

Checking fan blades for damage

Inspect the fan blades for any cracks or damage. Damaged blades can lead to reduced cooling efficiency and potentially damage other parts of the cooling system.

Assessing the operation of the fan clutch

Ensure that the fan clutch engages and disengages properly. A malfunctioning fan clutch can lead to overheating or excessive cooling.

Tips for proper fan maintenance

Regularly check the fan and clutch for wear and tear, and replace them as necessary. Keeping these components in good condition is essential for effective cooling.

Belt and Pulley Inspection

Belts and pulleys drive the water pump and fan, crucial components of your big rig’s cooling system.

Looking for signs of wear on belts

Inspect the belts for signs of wear, such as cracks, fraying, or glazing. Worn belts can lead to cooling system failure.

Ensuring pulleys are in alignment

Check that the pulleys are aligned and in good condition. Misalignment can cause belts to wear prematurely and reduce efficiency.

Replacing belts and pulleys when necessary

Replace any worn belts or damaged pulleys promptly to maintain optimal cooling system performance.

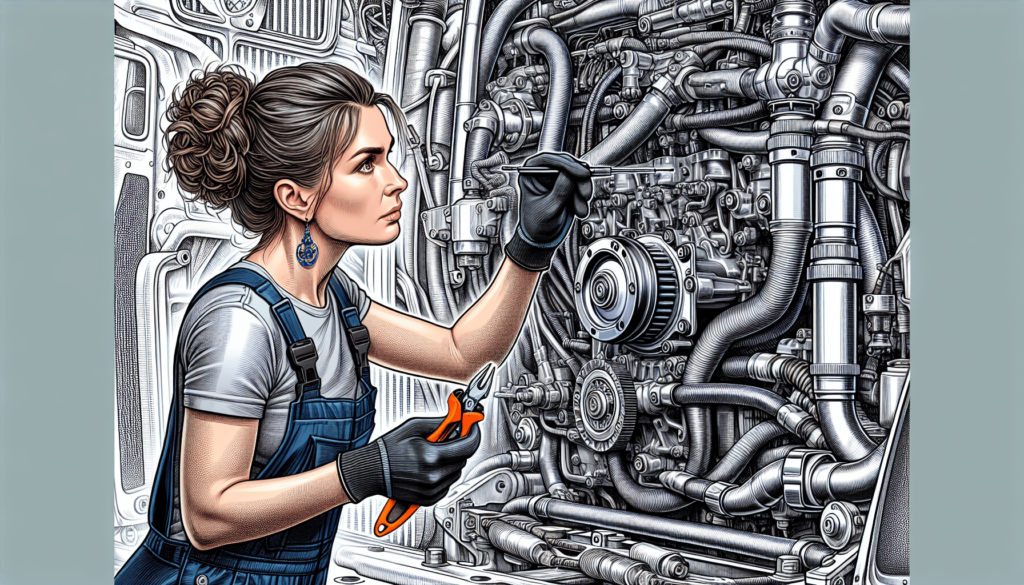

Professional Maintenance and Repair

Sometimes, it’s best to seek professional help to maintain your big rig’s cooling system.

When to seek professional help

If you’re unsure about a potential issue or lack the tools and expertise for certain maintenance tasks, don’t hesitate to seek professional assistance.

Choosing the right service for your big rig

Select a reputable service center that specializes in big rigs and has experience with your specific make and model.

The importance of regular professional checkups

Regular professional checkups can help catch issues early, saving you time and money in the long run and ensuring your cooling system operates efficiently throughout the year.